Parts Of Ship

Table of contents

Imagine ships as sprawling seafaring towns, setting sail across boundless oceans to accomplish vital global missions. These impressive vessels consist of a medley of both apparent and concealed parts of the ship, working in beautiful harmony to orchestrate their remarkable journeys. Visualize the ship as a collaborative endeavor, with key players like the hull, engine room, and navigation bridge comprising the sturdy foundation of its makeup. While some standout features like the rudder, anchor, and mast take center stage, there are unsung heroes like bulkheads and cofferdams laboring quietly behind the scenes, ensuring unwavering stability and enduring strength. It’s a captivating realm of ship components, akin to pieces of a grand puzzle, coming together to weave a tapestry of seamless and unforgettable maritime adventures around the globe.

Bow of the Ship:

One of the integral parts of a ship is its bow, which constitutes the forward segment designed to effortlessly slice through water. Positioned at the forefront of the hull, the bow plays a pivotal role in diminishing resistance and enhancing maneuverability. The configuration of the bow, be it pointed, rounded, or bulbous, is tailored to the ship’s intended function, aiding in efficient navigation through waves and the preservation of stability. Undoubtedly, the ship’s bow emerges as a vital component for ensuring the secure and efficient traversal of water, solidifying its status as an indispensable aspect of every maritime vessel.

Purpose and Function of the Bow:

The bow of a ship serves a crucial role in maritime engineering, fulfilling various essential functions that contribute to the vessel’s overall performance and safety. The water is efficiently cut through by the bow, which is designed as the foremost part of the hull, thereby reducing resistance and improving hydrodynamics. This streamlined shape enables the ship to achieve higher speeds while optimizing fuel efficiency, making it economically viable for extended voyages.

Beyond hydrodynamics, the bow plays a vital role in maintaining stability. By displacing water in a way that counteracts the forces acting on the stern, a well-designed bow ensures a balanced distribution of weight, minimizing the risk of capsizing or excessive rolling and pitching. This stability is of paramount importance, especially in rough seas or adverse weather conditions, providing a safe and comfortable journey for passengers and crew.

Overall, the bow’s primary functions encompass optimizing hydrodynamics for speed and efficiency while enhancing stability for safe and reliable performance during maritime operations.

Design and Hydrodynamics:

The design of the ship’s bow is meticulously engineered to optimize its hydrodynamic performance. The shape and contours of the bow are carefully crafted to minimize drag and wave-making resistance, enabling the vessel to move through the water with reduced energy expenditure. This hydrodynamic efficiency translates to higher speeds and improved fuel economy, critical factors for commercial and military ships alike.

The bulbous bow design is one such innovation used to further enhance hydrodynamics. By protruding below the waterline, the bulbous bow modifies the wave patterns, reducing drag and enhancing the vessel’s overall performance. Additionally, the bow’s shape influences how the ship handles waves, allowing it to cut through them smoothly and maintain stability in challenging sea conditions.

Engineers also consider the bow’s interaction with other hull sections, propellers, and appendages to ensure a streamlined flow of water around the ship. These careful design considerations contribute to the ship’s overall efficiency and performance, enabling it to operate economically and effectively throughout its service life.

Stability and Performance:

The bow’s design significantly impacts the ship’s stability and overall performance. As the forwardmost part of the ship, the bow’s weight distribution and shape play a vital role in maintaining equilibrium of the ship. By displacing water downward and outward, the bow counteracts the forces exerted on the stern, helping the ship remain steady and balanced in various sea conditions.

Stability is particularly crucial for ensuring the safety of the ship, crew, and cargo. A well-balanced bow reduces the risk of rolling or pitching, providing a comfortable and secure voyage for passengers. Moreover, stability is a critical consideration in the efficient operation of the ship, as it influences factors such as fuel consumption, cargo handling, and navigational control.

Engineers strive to find an optimal balance between the bow’s hydrodynamic efficiency and its stability-enhancing characteristics. This delicate equilibrium results in a vessel that performs well across a range of sea conditions while ensuring the safety and comfort of those on board.

Stern of the ship:

The stern of a ship is the rear section of the hull, opposite the bow. It plays a crucial role in maritime engineering, encompassing various functions that contribute to the vessel’s overall performance and safety.

Role and Importance of the Stern:

The stern serves several essential purposes in ship design. It houses the ship’s propulsion systems, rudders, and other mechanical components responsible for steering and maneuvering the vessel. The stern’s shape and design influence the ship’s hydrodynamics, optimizing its performance by reducing drag and improving stability. Additionally, the stern often accommodates crew quarters and operational spaces, making it a vital area for onboard living and working conditions.

Propulsion Systems at the Stern:

The stern is a critical location for housing propulsion systems. Most ships have their main engines and propellers situated at the stern, as this placement allows for efficient power transmission and maneuverability. The propellers, driven by the engines, generate thrust that propels the ship forward or backward. In some cases, ships may have additional thrusters at the stern, aiding in precise maneuvering, especially during docking or intricate maritime operations.

Significance of Stern Markings:

Stern markings on a ship are essential for identification and safety purposes. The ship’s name, registration number, and port of registry are commonly displayed on the stern. These markings help in identifying the vessel from a distance and during port inspections. Additionally, large and visible stern markings play a crucial role in collision avoidance, allowing other vessels to identify and take appropriate action in crowded waterways or adverse weather conditions.

To know more about different types of ships and their parts check out the page; TYPES OF SHIP

Superstructure:

In maritime terms, the superstructure refers to the part of a ship or boat that is situated above the main deck level. It encompasses various spaces that serve essential functions for the vessel’s operation, crew accommodations, and navigation. Unlike the hull, which is primarily responsible for buoyancy and cargo storage, the superstructure provides habitable spaces and operational areas required for the crew’s comfort and safety.

Types and Variations of Superstructures:

Superstructures can vary significantly based on the type and purpose of the ship. In passenger ships, the superstructure may include multiple decks housing cabins, lounges, dining areas, and recreational facilities. On cargo ships, the superstructure may be more streamlined, with a focus on efficient cargo handling and storage spaces.

Warships often have complex superstructures, accommodating various equipment, command centers, and weapon systems. Research vessels might feature specialized superstructures to accommodate laboratories and scientific equipment.

In modern vessels, superstructures are often constructed using lightweight materials such as aluminum or composites to minimize weight and enhance performance.

Functions and Components within the Superstructure:

The superstructure serves several crucial functions. It provides living quarters for the crew, including cabins, mess rooms, and recreational spaces. It also houses essential operational areas like the bridge, where navigation and control of the vessel occur. The bridge is equipped with navigation instruments, communication systems, and controls for propulsion and steering.

Other components within the superstructure include crew amenities like galleys (kitchens), medical facilities, offices, and storage areas. It also accommodates safety features such as lifeboat stations and muster stations.

The design of the superstructure ensures the comfort and safety of the crew during their time at sea. Its layout and arrangement are carefully planned to optimize space, facilitate efficient operations, and maintain stability and seaworthiness.

In summary, the superstructure is a vital part of any ship, providing habitable spaces for the crew and essential operational areas required for navigation and control. Its design varies depending on the vessel’s type and purpose, accommodating diverse functions and components crucial for the efficient and safe operation of the maritime vessel.

Bridge:

Embarking on a journey towards becoming a captain through a DNS or BSc in Nautical Science will lead you to the bridge – the pulsating heart of a ship, typically situated atop the superstructure. Within this command center, critical navigational and operational choices are forged, showcasing your expertise. The bridge unveils a sweeping panorama of the encircling waters, granting watchkeeping officers the ability to oversee the vessel’s trajectory, pinpoint looming risks, and harmonize actions with fellow ships.

Responsibilities of the Bridge Crew:

The bridge crew is responsible for the safe navigation and operation of the ship. The Captain or Master holds overall authority, but the bridge team, including officers and helmsman, plays a crucial role in executing commands. They monitor radar and other navigation equipment, plot the ship’s course, and maintain constant communication with other ships and shore-based authorities.

The Officer of the Watch (OOW) is a senior officer responsible for the ship’s safe passage while on duty. They must adhere to international maritime rules and regulations, avoid collisions, and handle any emergencies that may arise.

Navigation and Communication Equipment:

The bridge is equipped with advanced navigation instruments and communication systems. Radar provides real-time data on nearby vessels and obstacles, aiding collision avoidance. Electronic chart displays replace traditional paper charts, offering accurate and up-to-date navigational information.

The Global Positioning System (GPS) is used for precise positioning and navigation. Gyrocompass ensure accurate heading information, while Autopilot systems maintain the ship’s course automatically under normal conditions.

Communication equipment includes VHF radios for ship-to-ship and ship-to-shore communication, satellite communication for long-range connectivity, and emergency distress systems like EPIRB (Emergency Position Indicating Radio Beacon) for distress signal transmission.

The bridge crew’s effective use of these sophisticated tools ensures safe navigation and efficient operation of the vessel, contributing to a successful and secure voyage.

They are able to excel in their work because they are graduated from esteemed colleges of Maritime Industry.

Hull:

The hull is the main body of a ship or boat, providing buoyancy and housing cargo and passengers. Its structural integrity is paramount for the vessel’s seaworthiness and safety. The hull is typically constructed from steel, aluminum, or composite materials, designed to withstand the stresses of the marine environment. Regular inspections and maintenance are essential to ensure the structural integrity of the hull and to make sure that it remains free from corrosion or damage that could compromise the vessel’s safety.

Different Types of Hulls and Their Applications:

- Flat-bottom Hull: Also known as a “flat-bottomed” or “flat-hulled” hull, this type has a flat base, making it suitable for shallow waters. These hulls are commonly used in inland waterways and some small boats.

- Round-bottom Hull: This type of hull is rounded on the bottom, providing better stability and smooth movement through the water. However, it may not be as efficient for carrying heavy loads compared to other hull types.

- V-Shaped Hull: V-shaped hulls are designed with a sharp V-shape at the bottom, offering good stability and maneuverability. They are commonly found in powerboats and some small watercraft.

- Deep V-Hull: Similar to the V-shaped hull, the deep V-hull has a more pronounced V-shape, which enhances its performance in rough waters and provides a smoother ride.

- Round-bilge Hull: This hull design has a rounded bottom and smooth curves, combining the benefits of both round-bottom and V-shaped hulls, providing stability and maneuverability.

- Hard Chine Hull: Hard chine hulls have distinct, sharp angles where the sides meet the bottom, allowing for a larger deck space and good stability, commonly found in some sailing yachts and powerboats.

- Multi-Hull: Multi-hull ships have two or more hulls, such as catamarans (two hulls) and trimarans (three hulls). These designs provide excellent stability and load-carrying capacity, commonly used for large ferries and some sailboats.

- Semi-Displacement Hull: This type is a hybrid between a planing hull and a displacement hull. It combines some of the speed characteristics of planing hulls with the efficiency of displacement hulls, often seen in medium-sized yachts and some motorboats.

- Displacement Hull: Displacement hulls are designed to move through the water rather than ride on top of it. They are more fuel-efficient but slower, typically used in large cargo ships, tankers, and many sailboats.

- Planing Hull: Planing hulls are designed to ride on top of the water at higher speeds, reducing drag and increasing speed. They are commonly found in speedboats, water-skis, and some smaller boats.

Maintenance and Inspection of the Hull:

Regular maintenance and inspections are crucial for preserving the hull’s integrity and longevity. Hull cleaning helps prevent marine growth, which can increase drag and reduce fuel efficiency. Periodic inspections, including ultrasonic thickness testing, ensure the hull’s thickness remains within safe limits. Any signs of corrosion, cracks, or damage must be promptly addressed and repaired to prevent further deterioration.

Deck of Ship;

The deck is the uppermost horizontal surface of the ship or boat, providing the primary workspace for the crew. It is from where cargo is loaded and unloaded, and various shipboard operations are conducted. The deck also serves as an area for recreational activities and relaxation for passengers and crew during their leisure time at sea.

Deck Layout and Classification:

The deck’s layout depends on the vessel’s type and purpose. Passenger ships have expansive decks with amenities like swimming pools and lounges. Cargo ships have well-organized cargo decks with cranes and equipment for efficient cargo handling. Warships feature flight decks for aircraft operations and weapon systems. The deck is classified into different levels, such as main deck, upper deck, and forecastle, each serving specific functions on the ship.

Safety Measures and Deck Maintenance:

Safety on the deck is of paramount importance, with crew members trained in various safety procedures and equipped with personal protective equipment. Railings and safety barriers prevent falls overboard, and firefighting equipment is strategically placed to respond to emergencies promptly. Regular maintenance of the deck, including cleaning, painting, and repairing damaged surfaces, ensures a safe and conducive working environment for the crew and passengers. Safety drills and exercises are conducted regularly to familiarize the crew with emergency procedures, promoting a culture of safety on board.

Propulsion Systems:

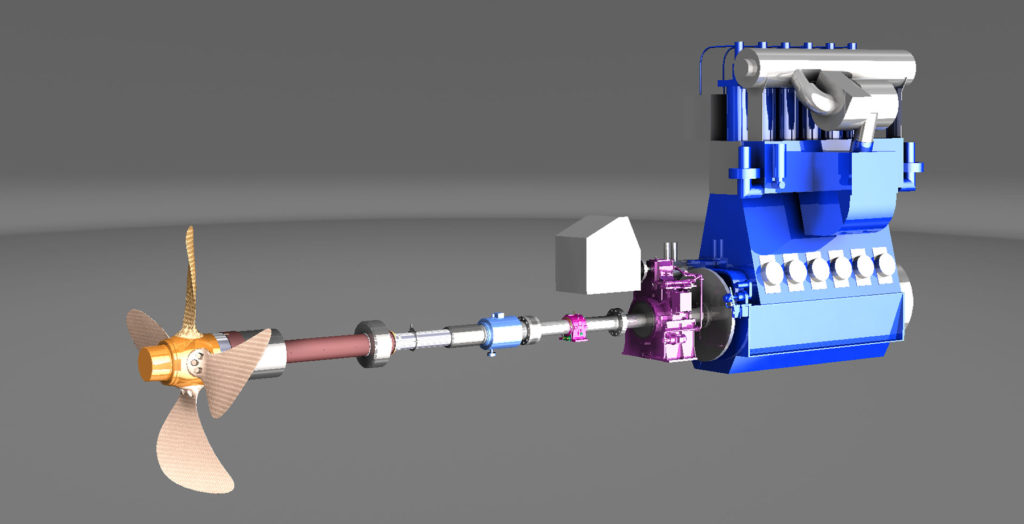

Propulsion systems in ships are responsible for generating the necessary force to propel the vessel through water. They play a vital role in determining a ship’s speed, efficiency, and maneuverability. There are several types of propulsion systems used in ships, including traditional systems like steam engines and diesel engines, as well as more modern technologies such as gas turbines and electric propulsion. Each system has its own advantages and disadvantages, depending on factors like the ship’s size, purpose, and intended use. Propulsion systems are crucial components of any ship, ensuring smooth and reliable transportation across the seas.

Propeller Design and Efficiency:

The propeller is a crucial element of a vessel’s propulsion system, and its design significantly impacts efficiency and performance. Engineers strive to create propellers that match the vessel’s unique specifications, including size, speed, and power requirements. A well-designed propeller optimizes thrust, reduces fuel consumption, and minimizes vibrations, contributing to smoother voyages and reduced environmental impact.

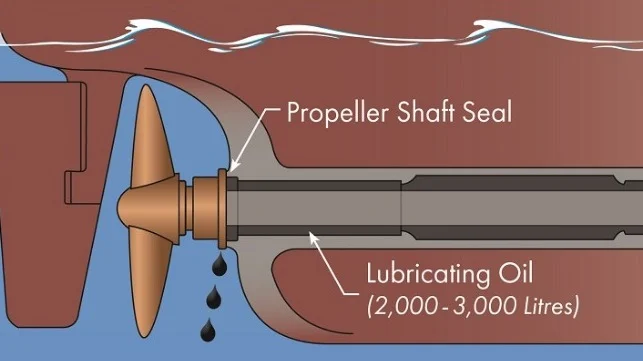

The propulsion shafting system plays a pivotal role in transferring power from the engine to the propeller. Proper alignment of shaft components is essential to prevent excessive wear, vibrations, and noise. Misalignment can lead to significant damage, affecting not only the shaft but also the engine and bearings. Regular maintenance and alignment checks are critical for ensuring optimal performance and avoiding costly repairs.

Propeller Maintenance and Repairs:

A well-maintained propeller is essential for the overall efficiency and safety of a vessel. Regular inspections and maintenance help identify early signs of damage, erosion, or fouling. Repairing small issues promptly prevents more extensive damage and ensures the propeller operates at its peak efficiency. Propeller repair techniques include polishing, balancing, and re-pitching, which restores its performance and extends its lifespan.

In conclusion, robust communication systems and well-maintained propellers and shafting are indispensable for the maritime industry. Embracing technological advancements and adhering to rigorous maintenance schedules ensure smooth operations, minimize downtime, and promote sustainability, making the seas safer and more efficient for everyone involved.

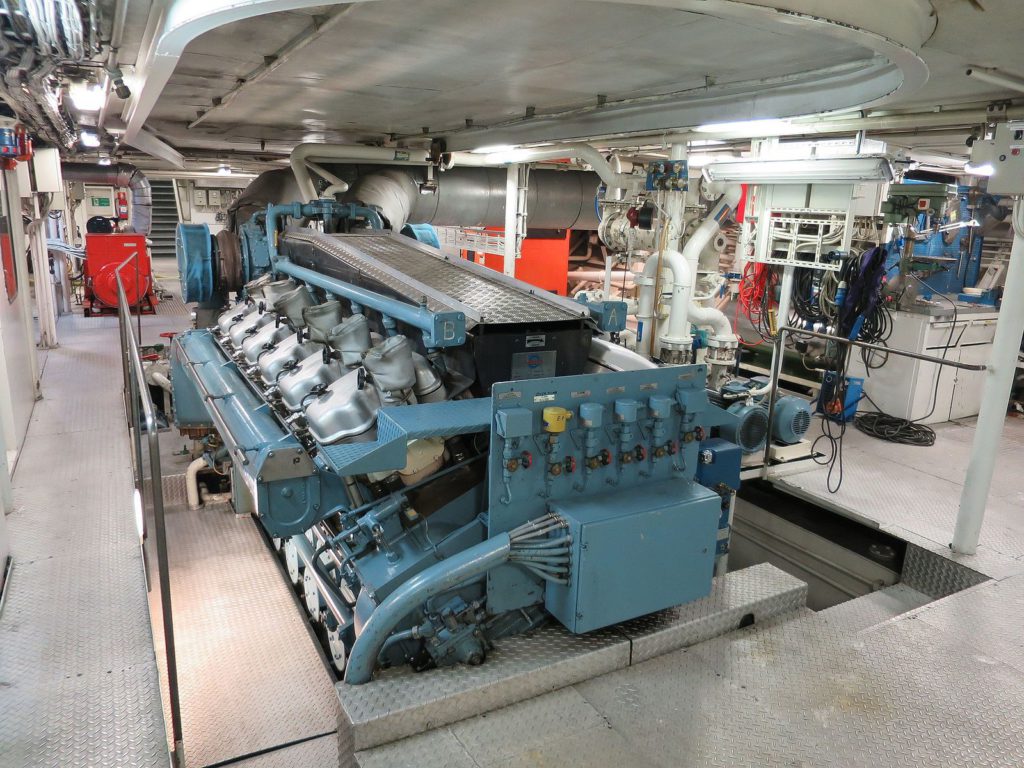

Engine Room and Power Generation:

Pursue a path to become a marine engineer and gain access to the heart of a ship – the engine room. This critical hub houses the ship’s main propulsion machinery and essential systems, functioning as a central nervous system where a variety of power generation equipment, including engines, generators, and auxiliary systems, are strategically positioned. These power generation systems play a pivotal role, generating electricity to energize a wide range of shipboard equipment and systems. Skilled engineers operate within the engine room, orchestrating seamless machinery performance and meticulous maintenance to ensure the ship’s unwavering reliability and safe navigation during its maritime journeys. Discover a fulfilling career where your expertise drives the operational excellence of these maritime giants. Becoming a marine engineer can be achieved through two strategic avenues. If you hold a B.Tech degree, the opportunity arises to engage in the Graduate Marine Engineering (GME) program. Alternatively, those with a direct inclination can opt for a B.Tech in Marine Engineering, setting a course for a rewarding maritime career.

Types of Propulsion Systems Used in Ships:

Ships utilize various propulsion systems, each with its own unique characteristics. Some common types include:

- Diesel Engines: Widely used for their efficiency and reliability, diesel engines burn diesel fuel to generate power.

- Steam Turbines: Although less common nowadays, steam turbines use steam to drive the propeller.

- Gas Turbines: These engines burn fuel to produce high-speed gas flow, which drives the propeller.

- Electric Propulsion: Electric motors connected to the propeller are powered by generators, providing better control and efficiency.

Want to know how these engines work:

Fuel Efficiency and Environmental Impact:

Fuel efficiency is a critical consideration for ships, as it directly affects operational costs and environmental impact. With that it also impacts the overall carbon footprint and emissions of a vessel. Modern ships employ technologies like advanced hull designs, energy-saving devices, and alternative fuels to improve fuel efficiency and reduce emissions. Additionally, the shipping industry is exploring sustainable alternatives such as LNG (liquefied natural gas) and hydrogen-powered ships to lower its environmental impact and comply with stricter emission norms.

Cargo Holds:

Cargo holds are designated spaces within a ship’s hull where cargo is stowed and transported. They are designed to securely store various types of goods during the voyage. Cargo holds vary in size and shape depending on the ship’s design and purpose. These holds are equipped with necessary infrastructure to facilitate loading, unloading, and securing of cargo.

Purpose and Types of Cargo Holds:

The purpose of cargo holds is to ensure safe and efficient transportation of goods across seas and oceans. Different types of cargo holds cater to specific types of cargo. For instance, liquid cargo requires specialized tanks, while dry bulk cargo demands open spaces. Containerized cargo is carried in cargo holds specifically designed to accommodate shipping containers securely.

Few more types of hold are as follow;

- Dry Bulk Cargo Hold: These cargo holds are designed to carry dry, unpackaged goods in bulk, such as grains, coal, ores, cement, fertilizers, and other similar commodities. They often have large open spaces without internal obstructions to facilitate efficient loading and unloading.

- Liquid Cargo Hold: Used primarily on tankers and chemical carriers, liquid cargo holds are designed to transport liquid cargoes such as oil, petroleum products, chemicals, and liquefied gases. They have specialized storage tanks to keep the liquids stable during transportation.

- Reefer Cargo Hold: These cargo holds are equipped with refrigeration or temperature-control systems to carry perishable goods, such as fruits, vegetables, meat, fish, pharmaceuticals, and other temperature-sensitive products.

- Container Hold: Commonly found on container ships, these cargo holds are designed to hold standardized shipping containers of various sizes. They allow for easy loading, unloading, and stacking of containers, making them efficient for intermodal transportation.

- Ro-Ro (Roll-on/Roll-off) Hold: Ro-Ro vessels have large cargo holds designed to carry vehicles, such as cars, trucks, buses, and other rolling equipment. They have ramps that allow vehicles to be driven on and off the ship directly.

- Livestock Cargo Hold: These specialized cargo holds are designed to transport live animals, such as cattle, sheep, and horses. They have ventilation and other facilities to ensure the well-being of the animals during the journey.

- Dangerous Goods Cargo Hold: Reserved for transporting hazardous materials, dangerous goods cargo holds have safety features to prevent leaks, spills, and reactions between different types of dangerous cargo.

Cargo Handling Equipment and Procedures:

Cargo handling equipment, such as cranes, forklifts, and conveyors, are used to load and unload cargo onto and from the ship. Efficient cargo handling procedures are essential to minimize turnaround times in ports and maintain the ship’s schedule. Safety protocols must be strictly adhered to during cargo operations to prevent accidents and injuries to personnel. Proper planning and coordination between ship crews and port authorities are necessary to ensure the smooth and timely handling of cargo.

Ballast System:

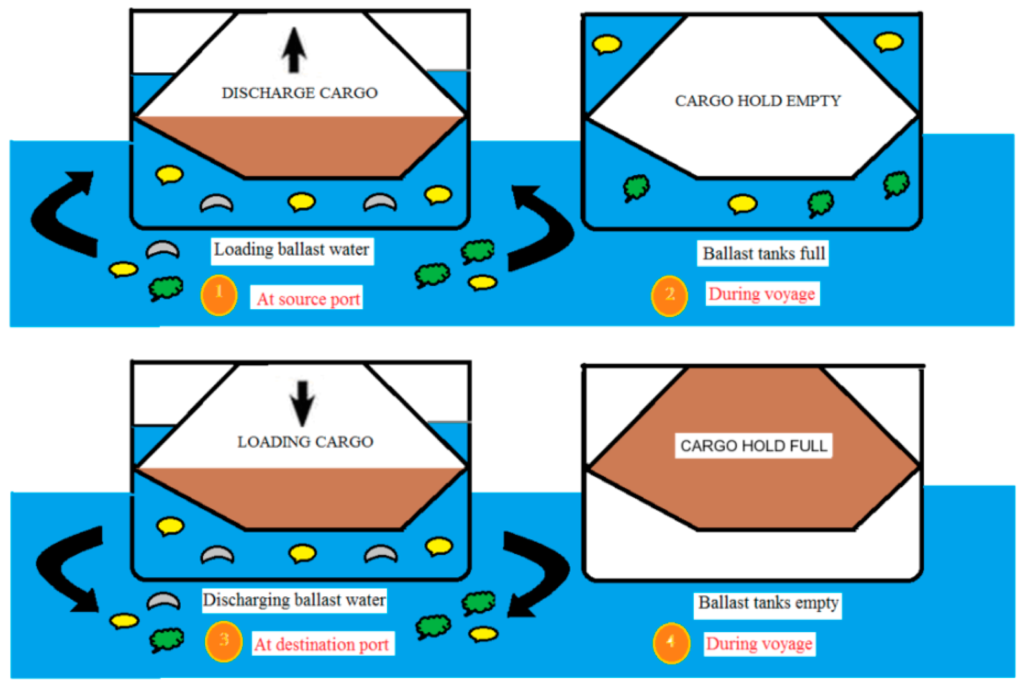

A ballast system in a ship is a vital component that helps maintain stability and balance. It involves the addition or removal of water, or other heavy materials, in dedicated ballast tanks to adjust the ship’s draft and trim. Proper ballasting is essential to ensure that the ship remains steady and upright, regardless of the varying loads, sea conditions, or cargo operations.

Importance of Ballast in Ship Stability:

Ballast plays a crucial role in maintaining a ship’s stability and preventing it from listing or capsizing. By adjusting the ballast, the ship’s center of gravity can be regulated, enabling it to counterbalance the forces acting upon it, such as wind, waves, and cargo weight. This balance is critical for safe navigation, smooth handling, and preventing accidents at sea.

Ballasting and De-ballasting Operations:

Ballasting and de-ballasting operations involve the filling and emptying of ballast tanks as per the ship’s requirements. During ballasting, seawater is pumped into dedicated tanks to increase the ship’s weight and draft. Conversely, deballasting involves discharging the water from the ballast tanks to reduce the ship’s draft and increase buoyancy. These operations are carefully managed to maintain stability and comply with maritime regulations.

Ballast Water Management and Environmental Concerns:

Ballast water management is a significant environmental concern in the shipping industry. It may carry various marine organisms, including invasive species, which can be discharged into new environments during ballasting or deballasting operations. This can disrupt ecosystems, harm local species, and impact biodiversity. To address this issue, international regulations and guidelines have been established to minimize the transfer of harmful organisms and pathogens through ballast water exchange and treatment.

Rudder and Steering Mechanism:

The rudder is a movable vertical plate located at the stern of the ship, and it is an essential part of the ship’s steering mechanism. It helps control the direction of the vessel during maneuvering, enabling it to turn left or right as required.

The rudder plays a pivotal role in ship maneuvering, especially during docking, undocking, and navigating through narrow waterways. When the ship’s propellers are engaged, the flow of water past the rudder causes a force that changes the ship’s direction.

Types of Steering Systems:

There are various types of steering systems used in ships, including:

- Mechanical Steering: Traditional systems that utilize mechanical linkages to connect the steering wheel to the rudder.

- Hydraulic Steering: More common in modern ships, these systems use hydraulic power to control the rudder.

- Electric Steering: Utilizes electric motors and sensors for precise and efficient control

Navigation and Control of the Rudder:

The rudder’s navigation and control are typically managed from the ship’s bridge, where the helmsman operates the steering wheel or uses electronic controls for newer systems. The bridge is equipped with advanced navigation tools and systems that aid in precise and safe maneuvering.

Anchors and Anchor Handling:

An anchor is a heavy object connected to the ship by a chain or cable. It is used to keep the ship in place by holding onto the seabed.

Anchors are crucial for a ship’s safety and stability, especially during periods of rest, or adverse weather conditions. They prevent the ship from drifting with currents. They also hold it securely in a specific location, allowing it to maintain a stable position.

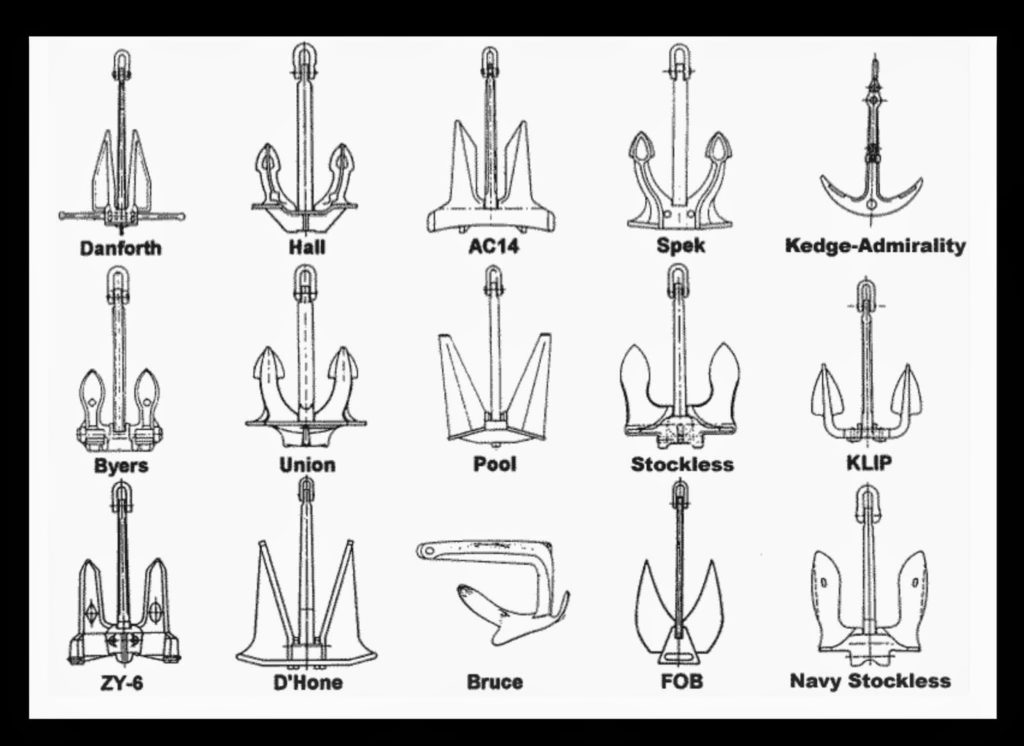

Anchor Types and Selection:

Different types of anchors are used depending on the seabed conditions and the ship’s size and type. Common anchor types include the stockless anchor, the stock anchor, and the mushroom anchor. The appropriate anchor is selected based on factors such as water depth, wind, and current conditions.

Lifeboats and Lifesaving Equipment:

Lifeboats and lifesaving equipment are essential elements of a ship’s safety measures. In case of emergencies, these equipment ensure the safe evacuation of crew and passengers. Lifeboats are specially designed, vessels that can be launched from the ship to provide a means of escape in emergencies. They are equipped with necessary supplies like food, water, and survival equipment to sustain the occupants until rescue arrives.

Lifesaving Equipment and Emergency Preparedness:

Ships are equipped with various lifesaving equipment, such as lifebuoys, life rafts, lifejackets, and immersion suits, to provide additional safety options during emergencies. Crew members undergo regular emergency drills and training to ensure they are well-prepared to handle critical situations.

Navigation Lights and Signals:

Navigation lights are essential visual aids used in maritime navigation, especially during night time and low visibility conditions. These lights help identify the type, size, and direction of the vessel, assisting in safe passage and collision avoidance.

Navigation lights are crucial for preventing collisions at sea and ensuring vessels can be identified and tracked by other ships, especially during periods of reduced visibility or darkness.

Understanding Maritime Signals and Markings:

Maritime signals and markings are used to communicate important information to other vessels. These may include day shapes, flags, and sound signals, all of which have specific meanings in international maritime regulations.

Navigational Rules and Regulations:

Navigational rules and regulations, governed by the International Regulations for Preventing Collisions at Sea (COLREGs), provide a standardized framework for safe navigation and collision avoidance between vessels. All ships are required to adhere to these rules to ensure maritime safety.

Radar and Navigation Equipment:

Radar technology is an essential tool for safe navigation at sea, providing real-time information about the ship’s surroundings, including other vessels, landmasses, and weather conditions.

These systems use radio waves to detect and track objects in the ship’s vicinity, helping the crew to make informed navigational decisions and avoid potential hazards. GPS, coupled with ECDIS, has revolutionized maritime navigation, providing accurate positioning data and electronic charts to aid navigation. These systems enhance situational awareness and route planning.

Marine Communication for Seamless Operations:

Efficient communication is the backbone of safe and smooth maritime operations. Marine communication systems have evolved significantly over the years, with advanced technologies ensuring real-time information exchange. VHF Radios, being a fundamental component, facilitate short-range ship-to-ship and ship-to-shore communication. They are vital for relaying navigational warnings, weather updates, and distress calls. Additionally, the Global Maritime Distress and Safety System (GMDSS) enhances safety at sea by automating distress alerting and search and rescue coordination. It integrates satellite communication, digital selective calling, and other communication methods to ensure comprehensive coverage.

Satellite Communication and Internet Connectivity:

Satellite communication has revolutionized the way vessels stay connected on the high seas. Offering global coverage, it enables voice communication, data transfer, and internet access for crew members and onboard systems. Reliable internet connectivity enhances navigational capabilities, allows for real-time weather updates, and enables seamless remote monitoring and diagnostics. Crew welfare also benefits, as sailors can stay in touch with loved ones during long voyages. However, with these advantages come challenges, such as satellite bandwidth limitations and potential signal disruptions due to adverse weather conditions.

Bilge System and Pumping:

The bilge system is a critical aspect of any vessel, responsible for managing water accumulation in the hull. It prevents water from adversely affecting stability and buoyancy by collecting it in the bilge area. The bilge pump plays a crucial role in removing this water from the bilge, keeping the vessel afloat and maintaining proper trim. Modern bilge systems are equipped with automatic pumps that activate when water levels reach a certain threshold, ensuring continuous monitoring and quick response to potential threats.

Managing Water in the Bilge Area:

Controlling water in the bilge area is crucial to prevent hazards and maintain the vessel’s structural integrity. Regular inspections are necessary to identify and address potential leaks, faulty valves, or damaged hulls that may lead to water ingress. Proper maintenance practices, such as keeping the bilge area clean and free from debris, help optimize pump efficiency and reduce the risk of clogs.

Types of Bilge Systems and Pumps:

Bilge systems come in various configurations to suit different vessel types and sizes. Some vessels may have multiple bilge compartments with separate pumps, while others might employ a centralized system. Electric submersible pumps and diaphragm pumps are common types used for bilge water removal. Understanding the unique requirements of each vessel is crucial to selecting the most suitable bilge system and pumps for optimal performance.

Bilge System Maintenance and Troubleshooting:

Regular maintenance is vital to ensure the reliability of the bilge system. Routine checks and tests should be conducted to verify the functionality of pumps, switches, and alarms. Bilge pump strainers and Strum Box must be cleaned to prevent blockages. Additionally, crew members should be trained in troubleshooting common issues to address any malfunctions promptly.

Fire Prevention and Safety Measures Onboard:

Fire prevention is of utmost importance in the maritime industry due to the potentially catastrophic consequences of onboard fires. Strict safety measures, such as smoking restrictions, proper stowage of flammable materials, and regular inspections of electrical systems, can significantly reduce the risk of fire incidents.

Firefighting Equipment and Techniques:

Vessels are equipped with an array of firefighting equipment, including fire extinguishers, hoses, hydrants, and fixed firefighting systems. Crew members should be proficient in operating this equipment and implementing various firefighting techniques, such as the use of different extinguisher types based on the class of fire.

Safety Drills and Training for Crew:

Effective safety drills and crew training are paramount for a well-prepared and responsive team. Regular safety drills ensure that crew members are familiar with emergency procedures and know how to handle critical situations, such as fire outbreaks and bilge flooding. These drills promote a safety-oriented culture and instill confidence in the crew’s ability to tackle emergencies.

Engine Room Ventilation: Importance and Purpose:

Engine room ventilation is a critical aspect of maritime safety, ensuring the efficient operation of machinery and the well-being of crew members. The engine room houses various powerful and heat-producing machinery, such as engines, generators, and pumps, which require a continuous flow of fresh air to prevent overheating and maintain optimal performance. Proper ventilation also helps remove potentially hazardous gases and fumes, maintaining a safe working environment for engineers and technicians.

Ventilation Systems and Air Circulation:

Effective ventilation systems in the engine room are designed to provide a constant supply of fresh air while expelling hot air and exhaust gases. These systems consist of intake vents, exhaust fans, and ducts that facilitate air circulation throughout the space. Ensuring the correct size and positioning of these components is crucial for maintaining an adequate air exchange rate, especially in enclosed areas.

Engine Room Atmosphere Monitoring and Control:

To ensure a safe environment, engine room atmosphere monitoring systems are employed to continuously measure gas concentrations, temperature, and humidity. Alarms are integrated into these systems to alert the crew in case of hazardous conditions, enabling prompt actions to mitigate potential risks. Additionally, automatic control mechanisms may adjust ventilation rates based on monitored parameters to maintain an optimal atmosphere inside the engine room.

Galley – The Ship’s Kitchen:

The galley is the heart of the ship, where food preparation takes place to nourish the crew during their journeys. The galley design is optimized for efficient use of space, and it is equipped with various cooking appliances, storage facilities, and sanitation areas. A well-organized galley contributes to crew morale, ensuring delicious and nutritious meals are served on time.

Food Safety and Galley Hygiene:

Food safety is paramount in the maritime industry, as improper handling and storage of food can lead to food borne illnesses that may affect the entire crew. Galley hygiene practices include proper storage of perishables, regular cleaning and disinfection of food preparation surfaces, and adherence to food safety standards. Crew members working in the galley are typically trained in safe food handling procedures to prevent contamination and maintain high standards of hygiene.

Freshwater Generation and Storage:

A reliable freshwater supply is crucial for sustaining life onboard a vessel, especially during long journeys. Freshwater can be generated through various methods, including desalination, reverse osmosis, distillation and Fresh Water Generator. Once produced, freshwater is stored in dedicated tanks to ensure an adequate and continuous supply for drinking, cooking, cleaning, and other essential onboard activities.

Desalination and Water Treatment Methods:

Desalination is a widely used process for converting seawater into freshwater. Reverse osmosis is one of the most common techniques, involving the removal of salt and impurities through a semipermeable membrane. Distillation, on the other hand, utilizes heat to vaporize freshwater, leaving behind salt and contaminants. Effective water treatment methods also include filtration, chlorination, and ultraviolet disinfection to further purify the freshwater supply.

Water Conservation and Sustainability:

Onboard water conservation practices are essential to minimize freshwater consumption and reduce environmental impact. Implementing water-saving measures, such as repairing leaks, using low-flow faucets and showers, and promoting crew awareness of water usage, can significantly contribute to sustainability and efficient freshwater management.

Waste Management: Effective Waste Disposal at Sea:

Proper waste management is vital for maintaining a clean and healthy marine environment. It involves categorizing waste into different types, such as garbage, oily waste, and sewage, and ensuring appropriate disposal procedures are followed. Waste disposal at sea should comply with international regulations to prevent marine pollution and protect marine life.

Types of Shipboard Waste and Their Treatment:

Shipboard waste can be broadly classified as solid waste, oily waste, and sewage. Materials such as plastic, paper, and food waste constitute solid waste, and individuals should segregate and store them appropriately before disposing of them at designated ports. Special treatment is necessary for oily waste originating from machinery and fuel tanks, often involving the utilization of oil-water separators. Sewage undergoes treatment to mitigate its environmental impact prior to its discharge into the sea.

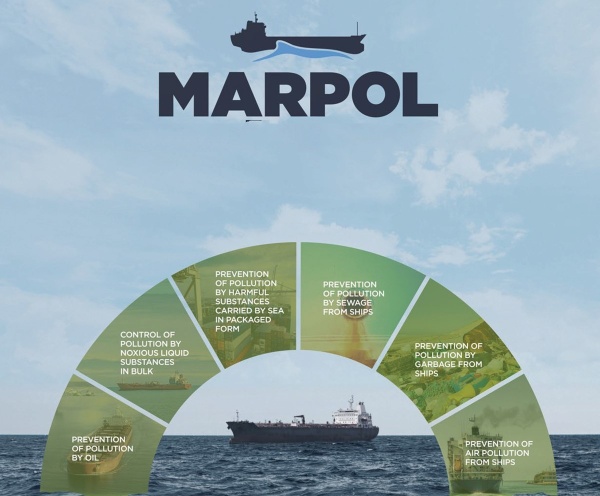

International Regulations and Environmental Compliance:

The maritime industry is subject to strict international regulations to preserve marine ecosystems and ensure environmental protection. The International Convention for the Prevention of Pollution from Ships (MARPOL) sets guidelines for waste disposal, ballast water management, and air emissions. Compliance with these regulations is essential for minimizing the industry’s ecological footprint and safeguarding the world’s oceans for future generations.

FAQs (Frequently Asked Questions) about Ships:

1. What are the different parts of a ship called?

Ships are composed of various components, each serving a specific purpose. Some common parts include the hull (the main body of the ship), the bow (the front), the stern (the back), the deck (the upper surface), the superstructure (above the main deck, housing crew quarters and navigation areas), and the engine room (housing the ship’s propulsion system).

2. How do ships stay afloat in water?

Ships stay afloat due to the principle of buoyancy. When a ship is placed in water, it displaces an amount of water equal to its weight. The ship’s hull, which is designed to have a shape that displaces water efficiently, allows it to stay buoyant and not sink. The weight of the ship is balanced by an equal and opposite force exerted by the water, keeping the ship afloat.

3. What is the purpose of the bridge on a ship?

The bridge is the navigational control center of a ship, typically located on the upper deck. It serves as the command post for the vessel’s navigation and communication. The ship’s officers, including the captain, use the bridge to monitor and control the ship’s course, speed, and overall operations. It houses various equipment like radars, GPS systems, charts, and communication devices to ensure safe and efficient navigation.

4. How are ships powered and propelled?

Ships are powered by different types of propulsion systems, depending on their size and purpose. Most modern ships use internal combustion engines that run on diesel fuel to generate power. This power is then transmitted to propellers or waterjets, which propel the ships forward or backward. Large ships, like container ships and oil tankers, may also have gas turbines or nuclear reactors for propulsion.

5. Why do ships use ballast water?

Ballast water is used to improve a ship’s stability and maneuverability. When a ship is not carrying a full cargo load, it may become top-heavy and prone to rolling in rough seas. To counterbalance this, ballast water is taken on board and pumped into ballast tanks, adding weight to the ship’s lower portion. When the ship is fully loaded, ballast water is discharged to allow it to float at the correct waterline.

6. What safety measures are in place in case of emergencies at sea?

Ships are equipped with a range of safety measures to handle emergencies at sea. These include lifeboats and life rafts for evacuating passengers and crew, life jackets and personal flotation devices for individual safety, emergency communication devices, fire suppression systems, and evacuation procedures. Additionally, ships are required to follow international safety regulations outlined in the International Convention for the Safety of Life at Sea (SOLAS) to ensure the highest level of safety standards. Crew members are trained in emergency response procedures, and regular safety drills are conducted to ensure readiness for any potential crises.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.

[…] to a sailboat’s architecture are its hull and deck. Just like any other part of the ship, the hull, the vessel’s main body, ensures stability and buoyancy, directly influencing […]