Types of engine

Engines are the heart of various machines and vehicles, powering them with the energy needed for operation. Over the years, several types of engines have been developed, each designed to suit specific applications and requirements. Understanding the different types of engines is crucial for selecting the most suitable power source for a particular task.

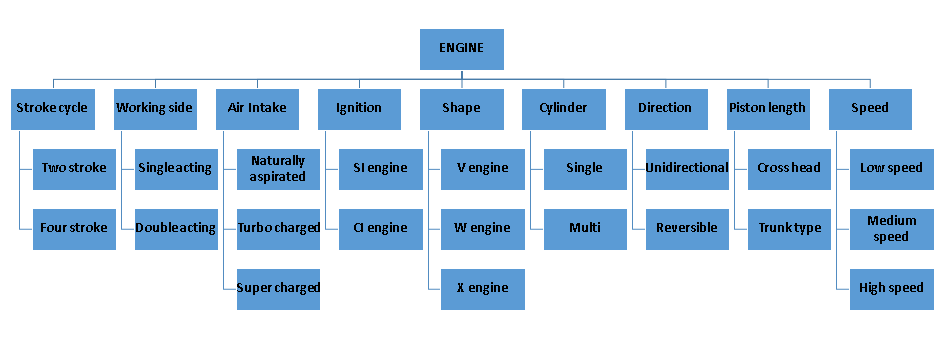

Classification of IC engines

1. Based on type of stroke:

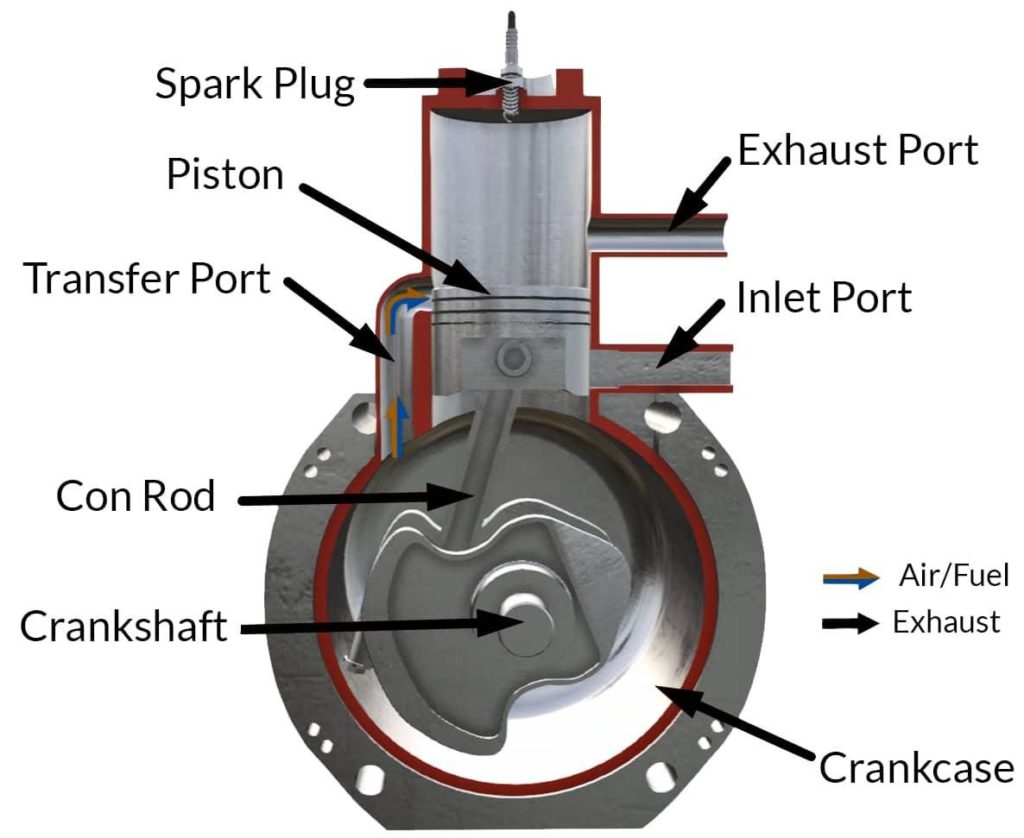

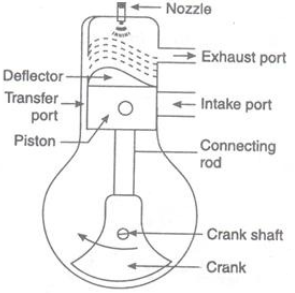

Two-stroke engine: A two-stroke engine is a type of internal combustion engine that completes a power cycle in two strokes instead of four strokes, as in a four-stroke engine. The two strokes are the compression stroke and the power stroke, which occur in one revolution of the crankshaft.

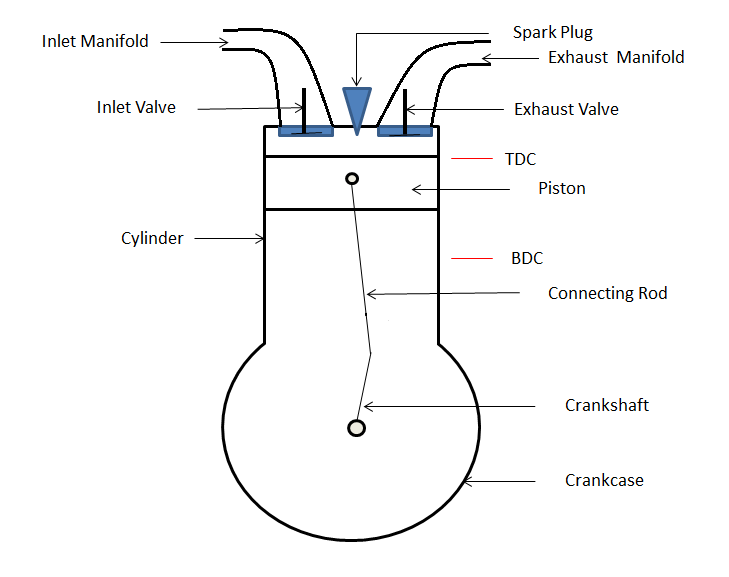

Four-stroke engine: A four-stroke engine is a type of IC engine that completes a power cycle in four strokes of the piston. The four strokes are the intake stroke, compression stroke, power stroke and exhaust stroke, which occur over two revolutions of the crankshaft.

2. Based on working side:

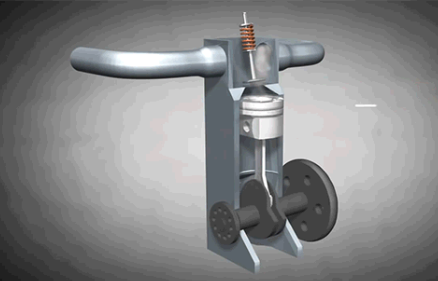

Single-acting engine: A single-acting engine is a type of internal combustion engine that operates with a simpler design compared to other engine configurations. It utilizes a single direction of force during the power stroke to generate mechanical work. In this engine, the combustion process occurs on one side of the piston, and the resulting expansion pushes the piston in one direction, producing power. The opposite stroke, known as the exhaust stroke, is achieved through gravity or an external force. Single-acting engines are commonly used in small-scale applications such as pumps, compressors, and certain types of steam engines. They are known for their straightforward construction and operation.

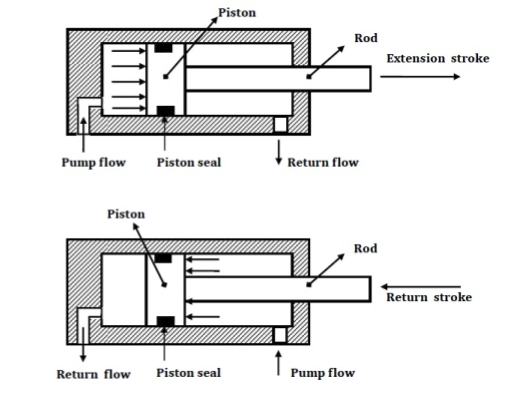

Double-acting engine: A double-acting engine is an engine that uses both sides of a piston to generate power. Unlike single-acting engines that work on one side of the piston, double-acting engines utilize both sides to maximize efficiency. They have a valve system that allows gas to enter and exit on both sides of the piston, ensuring high-pressure gas is admitted during each stroke. This design enables the engine to produce power on both the upward and downward strokes of the piston, making it more efficient than single-acting engines.

3.Based on air intake:

Naturally aspirated engine: A naturally aspirated engine, also known as an NA engine, is an internal combustion engine that relies solely on atmospheric pressure to draw air into the combustion chamber. It does not use any forced induction methods such as a turbocharger or supercharger to increase the air intake. In a naturally aspirated engine, the air-fuel mixture is drawn in through the intake manifold due to the downward movement of the piston during the intake stroke.

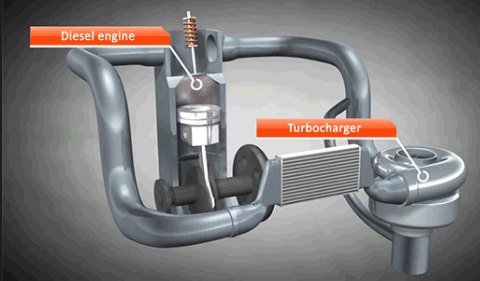

Turbocharged engine: A turbocharged engine is an internal combustion engine that uses a turbocharger to increase the amount of air entering the combustion chamber. The turbocharger consists of a turbine and a compressor connected by a shaft. The turbine is driven by exhaust gases, which powers the compressor to compress and force more air into the engine.

By increasing the air intake, a turbocharged engine can burn more fuel, resulting in more power and torque. This allows for better performance, especially at high speeds and altitudes. Turbocharging can also improve fuel efficiency by extracting more power from the same amount of fuel.

Supercharged engine:

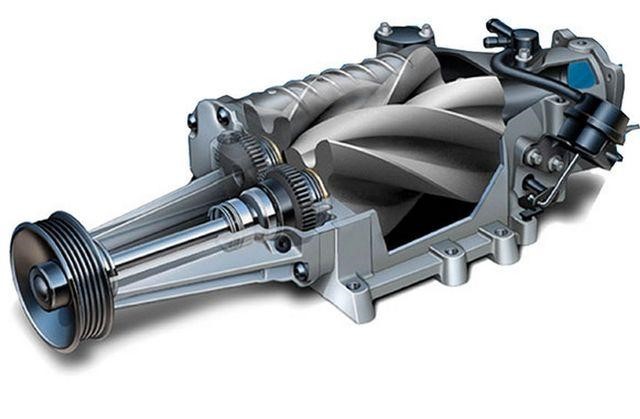

A supercharged engine is an internal combustion engine that uses a supercharger to increase the amount of air and fuel mixture entering the combustion chamber. A supercharger is a mechanical device that is driven by the engine’s crankshaft and compresses the air before it enters the cylinders.

The supercharger forces more air into the engine, allowing it to burn more fuel and produce more power. This results in improved performance, especially at low engine speeds where there may be insufficient airflow. Supercharging can provide instant throttle response and enhanced power throughout the engine’s rpm range.

4.Based on type of ignition:

Compression Ignition Engine:

A compression ignition engine, also known as a diesel engine, is an internal combustion engine that ignites fuel through the heat generated by compressing the air-fuel mixture. Unlike a spark ignition engine (such as a gasoline engine) that uses a spark plug to ignite the mixture, a compression ignition engine relies on the high compression ratio to generate enough heat for self-ignition.

In a compression ignition engine, air is drawn into the combustion chamber during the intake stroke. Then, the piston compresses the air, raising its temperature. At the top of the compression stroke, fuel is injected into the highly compressed air, and the mixture ignites spontaneously due to the high temperature and pressure. This combustion process produces high torque and efficiency.

Spark Ignition Engine:

A spark ignition engine, also known as a gasoline engine, is an internal combustion engine that ignites the air-fuel mixture using a spark plug. It operates by mixing fuel (gasoline) with air in the correct proportion and then igniting it with an electric spark.

In a spark ignition engine, the air-fuel mixture is drawn into the combustion chamber during the intake stroke. The mixture is then compressed by the upward movement of the piston. At the end of the compression stroke, a spark plug generates an electric spark, igniting the mixture and causing a rapid combustion process.

5.Based on shape of engine:

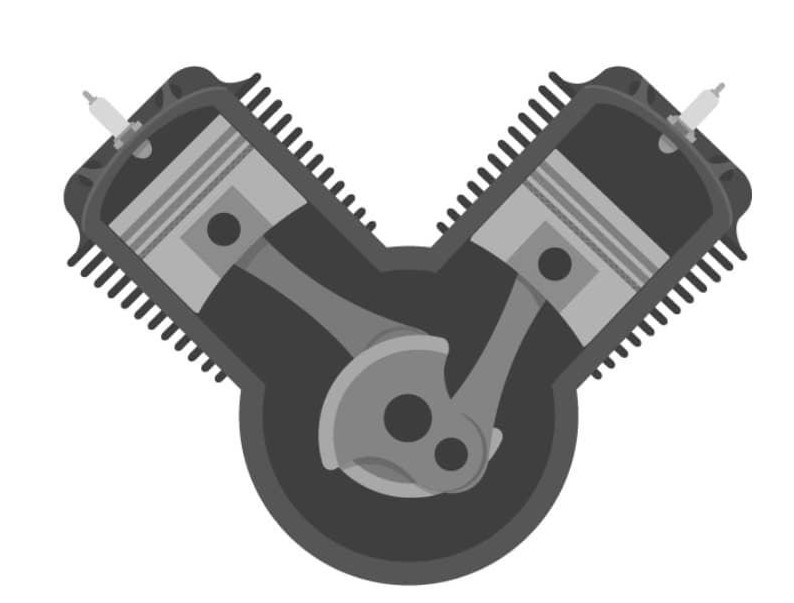

V engine: A V engine, also known as a V-shaped engine, is a type of internal combustion engine configuration where the cylinders are arranged in a V-shaped pattern. The cylinders are typically aligned at an angle, commonly 60 degrees or 90 degrees, forming two banks or rows.

V engines can be found in different cylinder configurations, such as V6, V8, V10, and V12, depending on the number of cylinders in each bank. These configurations offer varying levels of power, torque, and performance, catering to different vehicle types and applications.

V engines are widely used in a range of vehicles, including cars, trucks, SUVs, and motorcycles. They are popular in high-performance vehicles due to their ability to generate substantial power and torque output. The V engine configuration also allows for efficient intake and exhaust routing, contributing to improved performance. Overall, V engines offer a combination of compactness, balance, and power, making them a versatile choice for a wide range of applications.

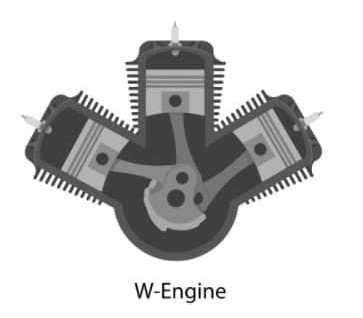

W engine: The W engine is a unique configuration of internal combustion engine that features three banks of cylinders arranged in a “W” shape. It is essentially a combination of two V engines joined together at a shared crankshaft.

The W engine configuration offers several advantages. Firstly, it allows for a higher cylinder count compared to a traditional V engine of the same length, resulting in increased power and performance potential. The three banks of cylinders can accommodate more cylinders, such as six, eight, or even twelve, depending on the design.

Secondly, the W engine offers improved packaging efficiency. The compact arrangement of cylinders allows for a shorter overall engine length compared to an inline or V engine with a similar cylinder count. This can be beneficial in applications where space is limited, such as sports cars or luxury vehicles. W engines are relatively rare and primarily found in high-performance and luxury vehicles. They offer a unique combination of power, compactness, and smoothness, catering to enthusiasts seeking exceptional performance and refinement.

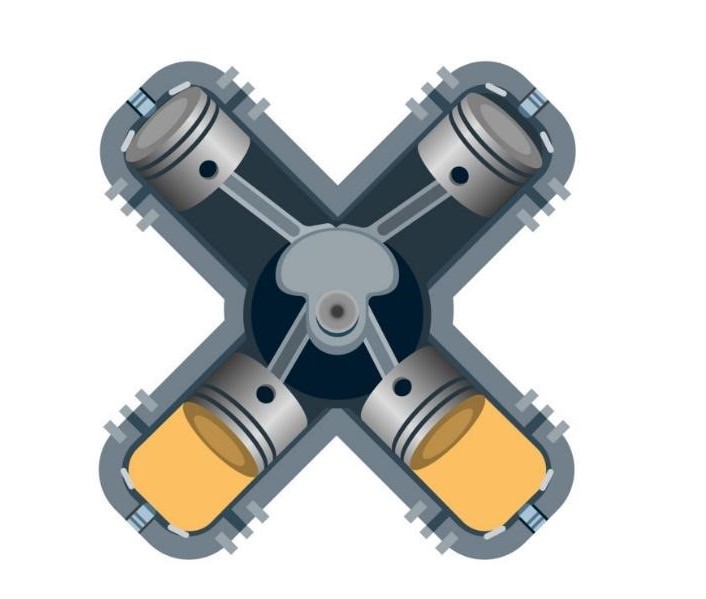

X engine:

An X engine is a piston engine with four banks of cylinders around a common crankshaft, such that the cylinders form an “X” shape when viewed from front-on.

The advantage of an X engine is that it is shorter than a V engine of the same number of cylinders, however the drawbacks are higher weight and complexity as compared to a radial engine. Therefore the configuration has been rarely used.

Several of the X engine designs were based on combining two V engine.

6.Based on number of cylinders:

Single-cylinder engine: A single-cylinder engine is an internal combustion engine that consists of a single cylinder for the combustion process. It is the simplest form of an engine configuration and is commonly used in various applications such as motorcycles, small generators, lawn mowers, and other lightweight equipment.

In a single-cylinder engine, the cylinder houses the piston, which moves up and down within the cylinder bore. The piston is connected to a crankshaft through a connecting rod, and the reciprocating motion of the piston is converted into rotational motion by the crankshaft. Overall, single-cylinder engines are widely used in lightweight and compact applications where simplicity, cost-effectiveness, and efficiency are key factors.

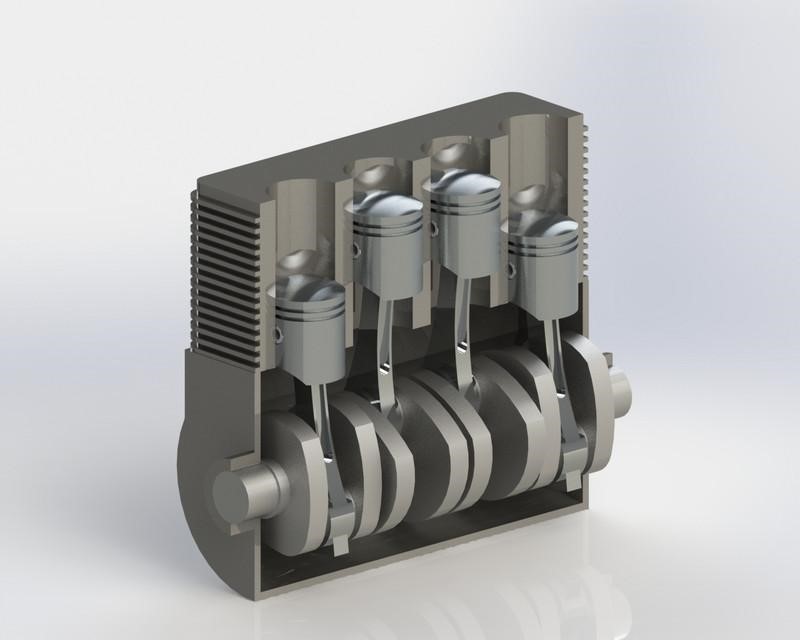

Multi-cylinder engine: A multi-cylinder engine is an internal combustion engine that consists of multiple cylinders for the combustion process. The cylinders are typically arranged in a specific configuration, such as inline, V, or flat (boxer).

Multi-cylinder engines offer several advantages over single-cylinder engines. They provide higher power output, smoother operation, better balance, and increased torque, resulting in improved performance. The larger number of cylinders allows for better distribution of work and a more even power delivery throughout the engine’s rpm range.

Multi-cylinder engines can be found in various vehicles and applications, ranging from small cars and motorcycles to high-performance sports cars and heavy-duty trucks. The specific configuration and cylinder count are determined by factors such as power requirements, vehicle size, and intended use.

7.Based on direction of stroke:

Unidirectional engine: Engines which run in only one direction are called Unidirectional engines like four-stroke engines. Non-reversible engines may lack features like a reverse gear or specific mechanisms for changing the direction of rotation. They are often designed for specific applications where reversing the engine’s rotation is unnecessary or impractical.

Reversible engines:

A reversible engine is an internal combustion engine that is designed and capable of operating in both forward and reverse directions. It has mechanisms and components that enable the engine to rotate in either direction.

In most reversible engines, the design incorporates a crankshaft and associated components that allow the pistons to move in both the upward and downward directions. This allows the engine to perform the power strokes and complete the combustion process in both forward and reverse rotations.

8.Based on connection to crankshaft:

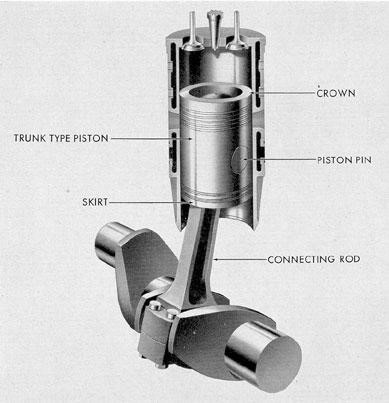

Trunk-type engine: In this engine, the upper part of the connecting rod is connected directly to the piston via the gudgeon pin It is used in a four-stroke engine which is an auxiliary engine in the ship.

In a trunk piston engine, the piston is typically short and has a larger diameter, resembling a trunk. This design allows for a larger combustion chamber and increases the power output of the engine. Trunk piston engines are commonly used in medium-speed marine propulsion systems.

The operation of a trunk piston engine follows the four-stroke cycle: intake, compression, power, and exhaust.

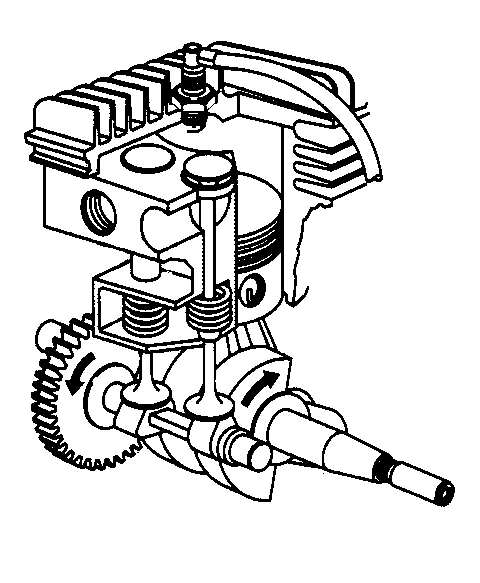

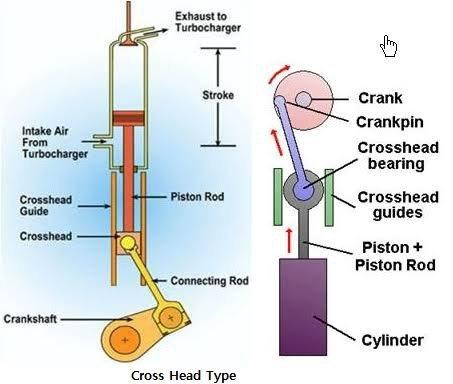

Crosshead engine: In this engine the piston rod is connected to a crosshead bearing and the bearing is connected to the crankshaft. The cross head bearing goes up and down when the piston moves up and down. It is used in two stroke engines for their long stroke length to burn bad fuel which needs time to burn.

In a crosshead engine, the crosshead assembly consists of a crosshead, connecting rod, and guide. The crosshead is a sliding component that connects the piston rod to the connecting rod. It allows the piston to move vertically within the cylinder while keeping it aligned with the crankshaft.

The primary purpose of the crosshead assembly is to reduce the lateral forces on the piston and cylinder walls, which helps minimize wear and improve the engine’s longevity. By separating the piston from the crankshaft, the crosshead assembly reduces friction and ensures smooth and efficient operation.

9.Based on engine speed:

Engines can be categorized based on their operating speed, often measured in revolutions per minute (RPM). Here are a few common types of engines based on RPM:

- High-Speed Engines: These engines typically operate at higher RPM ranges, often ranges between 750 and 2500 RPM or even several thousand RPM. They are commonly found in small vehicles, motorcycles, power tools, and some small generators. High-speed engines are designed for applications where compactness, lightweight, and quick power delivery are essential.

- Medium-Speed Engines: Medium-speed engines generally operate at RPM ranges between 350 and 750 RPM. They are commonly used in larger marine vessels, locomotives, heavy-duty generators, and some industrial applications. These engines provide a balance between power output and rotational speed and are designed for applications that require higher torque and durability.

- Low-Speed Engines: Low-speed engines typically operate at RPM ranges between 100 and 350 RPM. They are commonly found in large marine vessels, such as cargo ships, tankers, and cruise ships. These engines are designed to deliver massive amounts of power and operate at high efficiency. Low-speed engines have a large displacement and are known for their exceptional fuel economy and long service life.

Low speed engine – 100 to 350 rpm

Medium speed engine – 350 to 750 rpm

High speed engine – 750 to 2500 rpm

Normally the main engine in ship is a low speed engine and auxiliary engine is a high speed engine.

Note

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://www.merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.