Spark Ignition Engine vs Compressed Ignition Engine

Engines play a pivotal role in powering vehicles, machinery, and various other mechanical systems. Widely used, the two dominant types of engines are Spark Ignition engines and Compression Ignition engines. These engines differ fundamentally in their combustion processes, making them suitable for different applications and presenting unique characteristics and advantages. Furthermore lets see in detail about these engines.

What is the Spark Ignition engine?

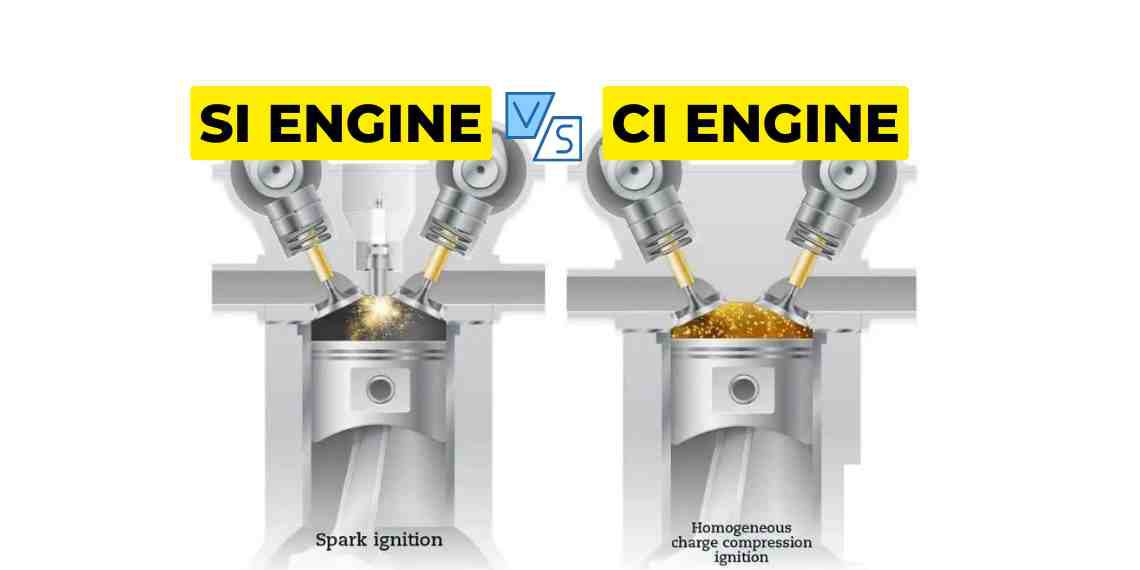

The Spark Ignition engine earns the name “Petrol engine” as it actively ignites the fuel-air mixture through a spark plug. It is a type of internal combustion engine that uses spark plugs to ignite a fuel-air mixture in order to generate power. Passenger cars, motorcycles, and small aircraft commonly employ SI engines for a variety of applications.

The basic operation of an SI engine involves four strokes: intake, compression, combustion, and exhaust. During the intake stroke, the fuel-air mixture is drawn into the engine’s cylinders. In the compression stroke, the mixture is compressed, which raises its temperature and pressure. And in the combustion stroke, the spark plug ignites the mixture, causing a rapid combustion that generates energy and forces the piston to move downward.

Finally during the exhaust stroke, the engine expels the spent gases, while the engine’s carburetor or fuel injection system actively controls the fuel-air mixture. The fuel-air mixture actively adjusts based on factors such as engine speed, load, and other considerations.

What is a Compressed Ignition engine?

Compressed Ignition engine is a type of internal combustion engine that compresses air in the cylinders, which causes the temperature to rise and ignite the fuel injected into the cylinder. Heavy-duty applications such as trucks, buses, ships, and generators commonly employ CI engines.

The basic operation of a CI engine involves four strokes: intake, compression, combustion, and exhaust. During the intake stroke, air is drawn into the engine’s cylinders. In the compression stroke, the air is compressed to a high pressure and temperature. And in the combustion stroke, fuel is injected into the cylinder, and the high temperature and pressure cause it to ignite spontaneously without the need for a spark plug.

Finally, during the exhaust stroke, the spent gases are expelled from the engine. CI engines run on diesel fuel, which is injected into the cylinder at a precise moment in the combustion cycle to ensure efficient ignition and combustion.

What are the differences between Spark Ignition engine vs Compression Ignition engine?

| Spark Ignition Engine | Compression Ignition Engine |

| 1. The compression ratio is 8-12 | 1. Compression ratio is 14-22 |

| 2. Otto cycle | 2. Diesel cycle |

| 3. A spark plug is used to generate ignition | 3. High-temperature ignition: Air is compressed to a high temperature for ignition |

| 4. Air and fuel petrol mixture is inserted through a carburetor | 4. First air is added then it is compressed and heated after that fuel is added |

| 5. Less compression takes place. So stroke length is shorter which leads to more speed of the piston | 5. More compression takes place. So stroke length is longer which leads to less speed of the piston |

| 6. Less maintenance (clean fuel, less carbon emission and piston rings remain clean) | 6. High maintenance (dirt in fuel) |

| 7. Less noise | 7. More noise |

Which engine is more used on ships?

In ships we use Diesel engine due to the following reasons:

- 1. Fuel efficiency: Diesel engines are more fuel efficient than petrol engines, which means that they consume less fuel to generate the same amount of power. This is important for ships, which require large amounts of fuel to operate over long distances.

- 2. Torque: Diesel engines produce more torque at low engine speeds than petrol engines, which makes them better suited for heavy-duty applications such as marine propulsion. This torque is important for driving the ship’s propellers efficiently.

- 3. Durability: Diesel engines outshine petrol engines in durability due to their design for high loads and heavy-duty conditions. This is important for ships, which operate continuously and often in harsh marine environments.

Note

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.