What is a centrifugal pump? Working & Parts of centrifugal pump | Uses of centrifugal pumps fitted on ships?

A centrifugal pump is a mechanical device that is used to transport fluids by converting rotational kinetic energy into hydrodynamic energy for fluid flow. The rotational energy typically comes from an engine or electric motor.

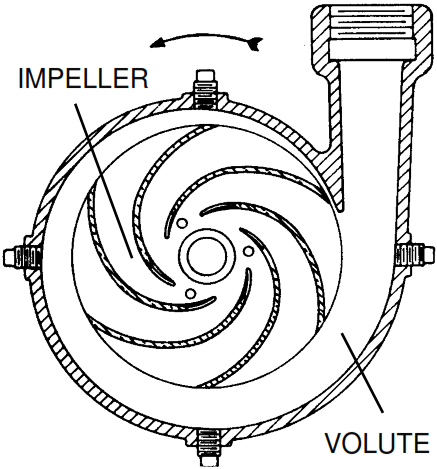

The fluid enters the pump impeller along or near the rotating axis and is accelerated by the impeller, flowing radially outward into a volute chamber (casing) from which it exits.

Here the suction and outlet/delivery angle is 90 degrees.

Centrifugal force Fc = mv2/r

where, m=mass of water,

r=radius of the impeller.

Parts of centrifugal pumps

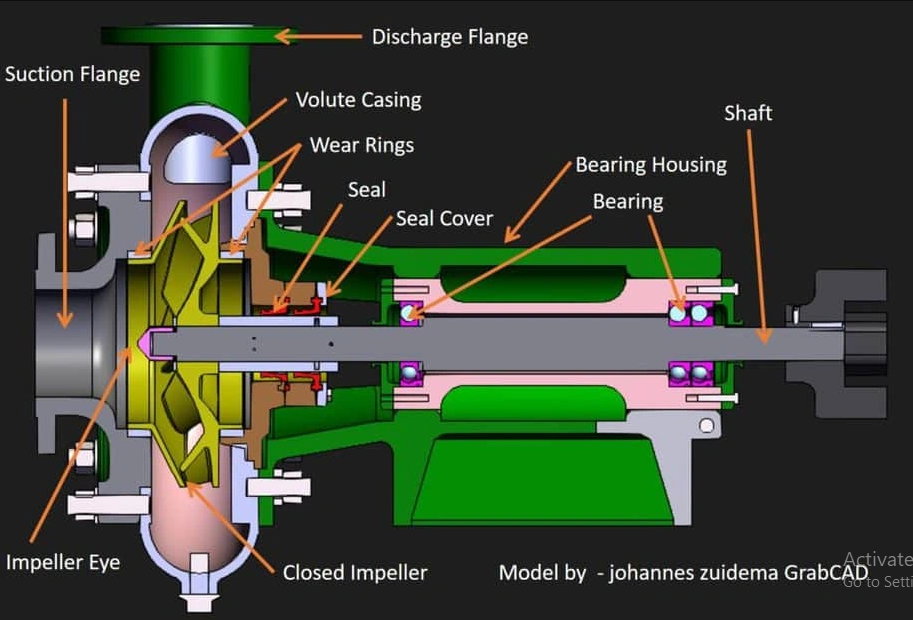

- Impeller- The rotating part of a centrifugal pump is called an impeller. It consists of a series of backwards-curved vanes. It is connected to the shaft of the motor.

2. Volute Casing- It is an air-tight passage surrounding the impeller and is designed in such a way that the kinetic energy of the water discharged at the outlet of the impeller is converted into pressure energy before the water leaves. Mainly volute, vortex, guideblade type casing is used.

3. Shaft- The shaft is the main rotating part of the pump, with the help of motors it transmits the power into the impeller.

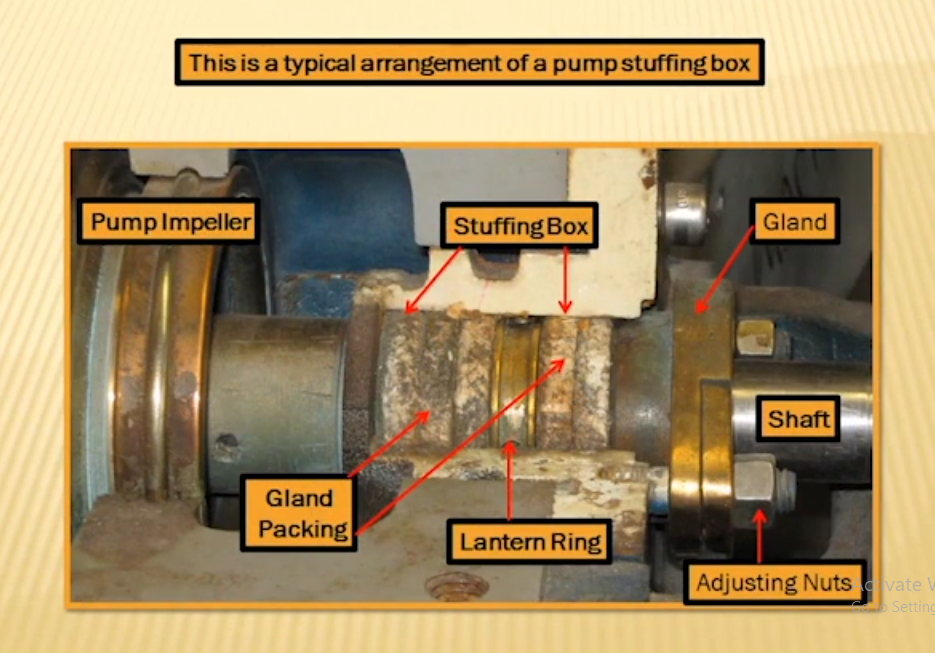

4. Shaft sealing : There are two types of shaft sealing.

a. Mechanical seal– Mechanical sealing is a sealing that is made with carbon and graphite and here a rotary part and a stationary part provide a very good sealing in many pumps.

b. Gland packing- The gland packing is a contact-type sealing element. Compared with other types of shaft seals they are adjustable and suitable for use with pressures and circumferential speeds higher than those radial shaft seal rings used for the shaft.

5. Lantern ring : Lantern ring is a metal ring that is fitted into the stuffing box for the following functions-

a) Cooling- Water from the discharge side of the pump is provided to the lantern ring which cools the shaft and the stuffing box.

b) Lubrication- It lubricates the gland packing

c) Protection of seal or packing- It acts as a flush point to flush out liquid to remove impurities which may enter through the stuffing box.

6. Bearing– Bearings are “parts that assist objects’ rotation”. They support the shaft that rotates inside the machinery. Machines that use bearings will take the load of the machine in their own body.

7. Suction pipe & delivery pipe– A inlet pipe whose one end is connected to the inlet of the pump and the other side is fitted in a sump or tank. A delivery pump is connected with the end of the casing or delivery point of the pump.

8. Strainer- A strainer is used in centrifugal pumps to prevent solid particles and debris from entering the pump’s internal components. This protects the pump from damage, maintains its efficiency, and reduces the need for frequent maintenance.

9. Foot valve- A foot valve is a non-return valve used in a pump to maintain the prime (liquid presence) in the suction line, preventing air from entering. It ensures continuous pumping and prevents back-flow, aiding in efficient and reliable operation, especially when drawing from sources below the pump’s level.

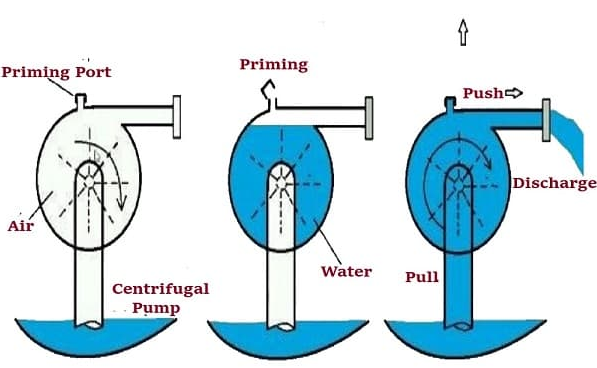

10. Priming port- A priming port in a centrifugal pump is a designated opening that allows you to add liquid directly to the pump and its suction line. This helps remove air and ensure efficient operation, particularly when the pump is above the liquid source or has been emptied.

Working of a centrifugal pump

When we start the pump the motor converts the electrical energy to mechanical energy, which rotates the shaft rotating the impeller. As the impeller rotates its pushes the water that is already present in the pump towards the volute casing due to which a void is created, this void is nothing but a negative pressure region which is at the eye of the eye of the impeller. As suction has taken place the impeller imparts centrifugal force to the liquid and it flows radially outwards away from the axis of the rotation due to which it gets kinetic energy.

Now the liquid flows through the volute casing, the cross sectional area of the volute casing is gradually increasing. From equation of continuity we know that when area increases velocity decreases, so when liquid flows through the volute casing the kinetic energy decreases and as soon as the kinetic energy decreases the pressure energy increases which is due to bernoulli’s theorem. Bernoulli’s theorem says that sum of all the energies in a liquid i.e potential energy, kinetic energy and pressure energy is constant.

Uses of centrifugal pumps fitted on the ship

Centrifugal pumps are not able to make very high pressure, but they can produce a high flow of fluid. For this reason, where we want a high flow of liquid there we use a centrifugal pump.

Examples are as follows;

- Main seawater pump: 2-3 bar.

- Fire and GS pump: 8-10 bar.

- Emergency fire pump: 8-10 bar.

- Main engine lube oil pump: 2-2.5 bar.

Note:

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://www.merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.

[…] curve of a centrifugal pump shows how the pump reacts as the load increases. When the load on the impeller increases, the motor uses more current for moving the impeller at a constant r.p.m so more power is […]

[…] oil pump is used to pump the lube oil up from the sump into necessary parts. A centrifugal pump is used because there is a need for a high amount of flow but high pressure is not […]