Lubrication of Two Stroke Marine Engine | Components of lubrication system | Working of lubrication in Main Engine | Important bearings that requires lube oil

Lubrication is the action of applying a substance such as oil or grease to an engine or component so as to minimize friction and allow smooth movement.

What is the need for lubrication in an IC engine?

- To reduce wear and tear.

- To dissipate heat.

- To avoid corrosion.

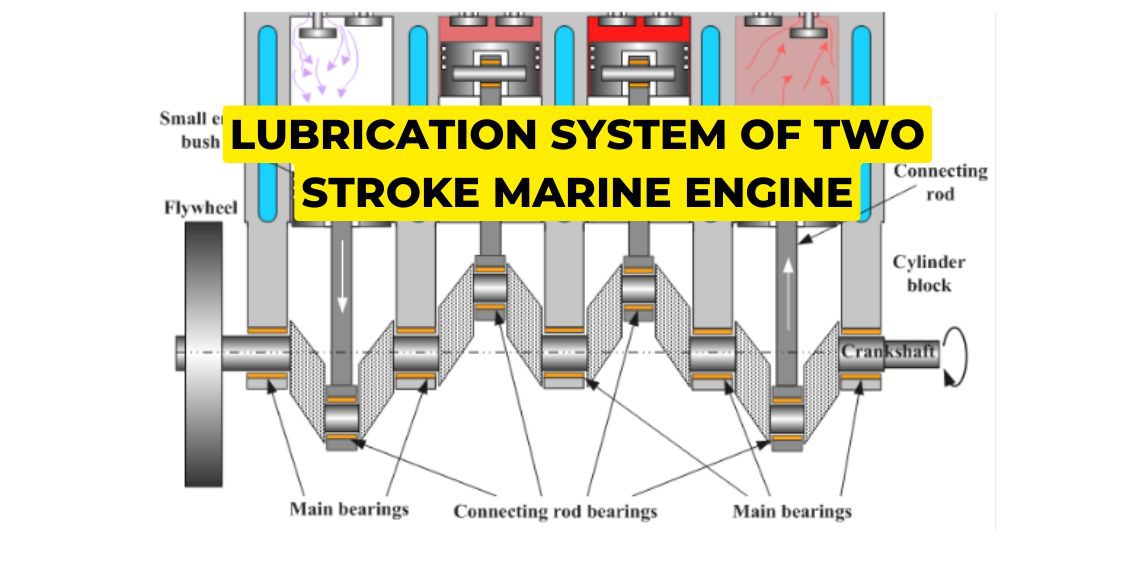

Three important bearings lubricated in a two stroke marine engine:

These three bearings use crankcase lube oil which is pumped from the Main Engine Oil Sump

Crosshead Bearing :

The reciprocating action of the piston is converted into rotary motion for crankshaft by means of the cross head where the piston rod and connecting rod are attached on both sides. A telescopic pipe is used to pump lube oil into the cross-head bearing as it is constantly reciprocating.

Crank-pin Bearing :

It is a mechanical device in an engine which connects the crankshaft to the connecting rod for each cylinder.

Main Bearing :

The main bearings are the bearings which hold the crankshaft in place and allow it to rotate within the engine block.

Apart from the above mentioned three bearings which are lubricated by crankcase oil, there is another place where lubrication is required in a two stroke engine and that place is between the piston and the cylinder liner. The lubrication between piston and cylinder liner is done using a separate oil called cylinder oil.

The crankcase oil that is used for lubrication of bearings, is in circulation continuously using the main engine lube oil pump. This oil is less basic with a TBN of around 6. This oil is continuously being purified on ship using the main engine lube oil purifier and we test this oil every week to check its condition. On the other hand, cylinder oil used is more basic with a TBN varying between 40-100 depending upon the sulphur content of the fuel oil being used for combustion. This cylinder oil is injected using quills and can never be reused again.

What are the components of a lubricating oil system in a two stroke marine engine?

Main Engine Sump

It is located under the engine and stores the crankcase lube oil which returns back to the sump after it has been used to lubricate the moving parts.

Lube Oil Pump

Lube oil pump is used to pump the lube oil up from the sump into necessary parts. A centrifugal pump is used because there is a need for a high amount of flow but high pressure is not necessary.

Lube Oil Cooler

Lube oil coolers function to remove excess heat from the oil, and therefore from engines or machines. Where oil becomes hot during a process, this heat exchanger cools the hot oil and returns it to the machine. It helps to ensure equipment and processes can continue safely without excess heat generation.

Filter

A very fine mesh of 50 microns is used to filter tiny impurities from the lube oil.

Cylinder Oil Tank

Lube oil stored in this tank is used to lubricate the area between the piston and the cylinder liner inside the combustion chamber. It is costlier than crankcase oil. It is highly basic and has a TBN of 40-100. It is not reused.

Working of lubrication system (main engine)

The lube oil is pumped up from the main engine sump using the lube oil pump and is passed through the lube oil filter where any sort of impurities present in the lube oil is removed. It is then passed onto the lube oil cooler to extract heat from the oil which has accumulated over previous cycles.

The oil then reaches the distribution manifold through which it goes to different parts of the engine which need lubrication. After the lube oil has lubricated the working parts it falls back down into the main engine sump so that the cycle can continue.

But this oil from the main engine sump is not used for lubricating the area between the piston and cylinder liner as discussed above, so a different lube oil with higher TBN is taken from the cylinder oil tank to lubricate this area and this oil is not used again like the oil in the main engine sump.

Note:

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.