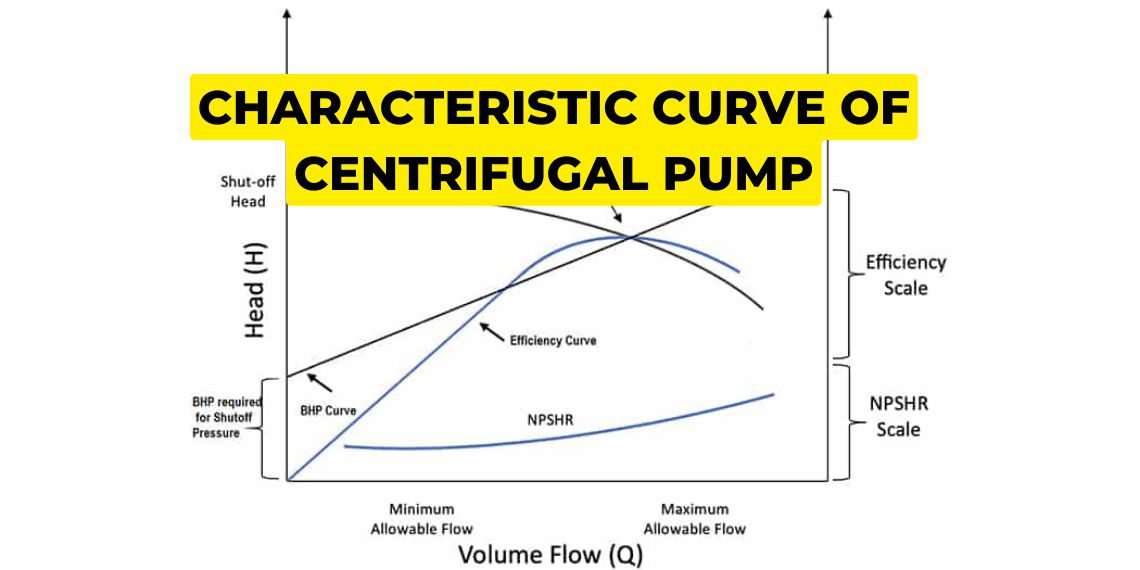

Characteristic curve of centrifugal pump used on ship | Why do we start a centrifugal pump with the discharge valve shut?

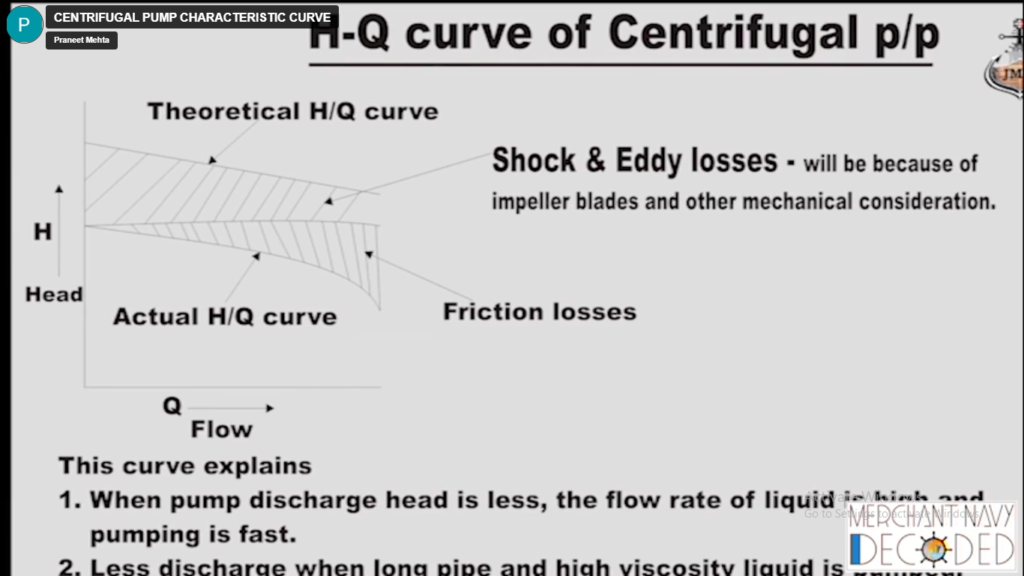

Theoretical and actual curve (Pressure and flow rate)

In the above characteristic curve we can see that as the flow rate increases pressure will be gradually decreasing, due to many factors like impeller blade thickness and other mechanical considerations the value of ‘H’ will be lower than the expected theoretical curve, this decrease in pressure head is called Shock and Eddy losses.

The fluid also has other properties like viscosity and frictional resistance which act on it the further it travels. These properties decrease the pressure head even further than the previous curve and we are finally left with the true characteristic curve of a centrifugal pump.

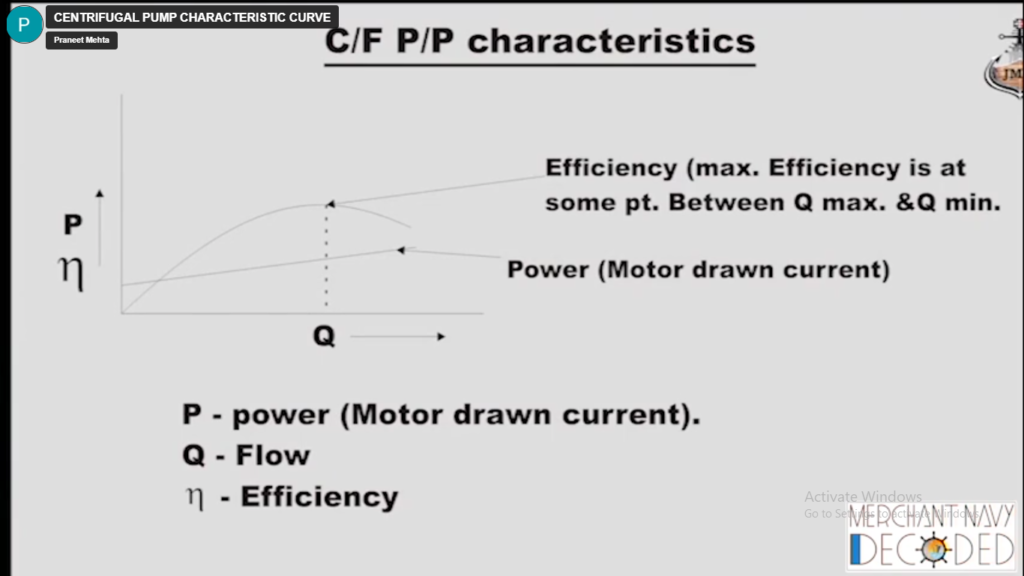

Efficiency curve

The efficiency curve of a centrifugal pump shows how the pump reacts as the load increases. When the load on the impeller increases, the motor uses more current for moving the impeller at a constant r.p.m so more power is needed as the load increases.

The efficiency curve represents the amount of flow rate we get for the different values of the power input. Usually, the most efficient part of a centrifugal pump is when we get an output equal to 70% of the Q max. This is the point where there is the most amount of flow for the least amount of power.

Why do we start a centrifugal pump with the discharge valve shut?

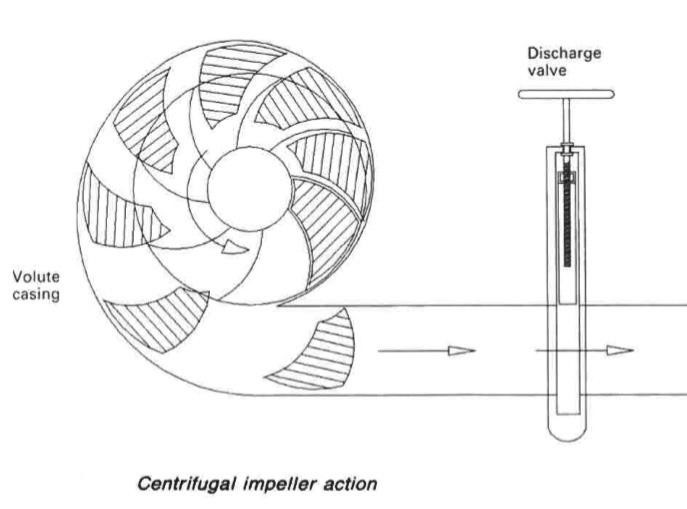

When we start a motor, the starting current drawn by the motor is very high as the motor has to overcome inertia at rest so more starting torque required. We also know that as per the characteristic curve of the centrifugal pump, that the current drawn by the motor of the centrifugal pump depends upon the amount of liquid flowing through the impeller eye.

Now if we start the centrifugal pump with the discharge valve shut there will be no flow through the eye of the impeller. As the water inside the casing will keep churning due to the discharge valve shut, it will result in no flow across the impeller eye.

So now when the motor is starting, it will only have to withdraw current for the starting torque but with no flow across the impeller, the motor will not have to draw excessive current needed in case there would have been flow of liquid across the impeller.

Go through the characteristic curve and you will see that when Q is 0, the current drawn by the motor is minimum.

Note:

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://www.merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.