Thread seal and grease

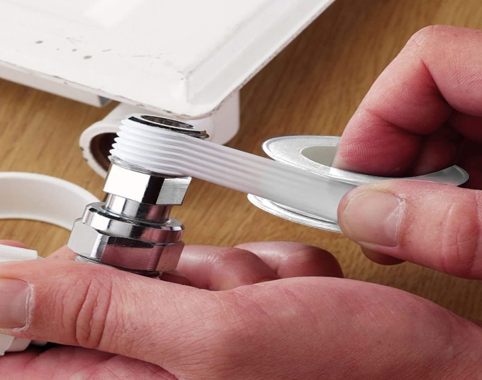

What is a thread seal?

It is a polytetrafluoroethylene (PTFE) film tape. Thread seal is a term used to describe the process of sealing threads on pipes, fittings, and valves to prevent leaks. Threaded connections are commonly used in plumbing and piping systems, and thread seal is essential to ensure that the connection is secure and leak-free.

Also known as Teflon/PTFE/ Plumbers Tape.

Functions :

1. For sealing pipe threads in plumbing.

2. Allowing the nut and bolt to be screwed deep together.

How to use: Typically the tape is wrapped around a thread 3 times before it is screwed/bolted. We get a right-hand thread bolt and apply the seal on the bolt thread opposite direction, which means the same direction as the screw thread. Otherwise, this seal does not properly overlap the bolt and nut thread gap.

Temperature Range: (-268 degree Celsius) to (+268 degree Celsius). Decomposition will occur in contact with open flames.

Limitation: Overuse can prevent mating threads from fully engaging.

What is grease?

Grease is a type of lubricant that is commonly used to reduce friction between moving surfaces. It is a semi-solid lubricant, that generally consists of a soap emulsified with mineral or vegetable oil.

The characteristic feature of a grease is that it possesses a high initial viscosity.

They are applied to mechanisms that cannot be lubricated frequently and

where a lubricating oil would not stay in position.

Types of grease used on ships:

Many types of grease are used on ships as per requirement.

Multipurpose grease:- For lubrication and protection of almost all kinds of gears nuts and many places it uses.

Extreme pressure grease:- lithium-based corrosion preventor extreme pressure additives. it will be used on the auxiliary engine piston connecting rod bolts which are tightened at very high pressure.

Gear grease:-It is a very highly viscous grease. which will be used on open gears rack. for that, it very sticks to the surface.

Low-temperature grease:– this type of grease is used for deck machinery for any temperature fall this grease is no fridge. it is suitable for roller and ball bearings.

Bearing grease:– this grease is very smooth with high oil content, and it resists from moisture.

Wire rope grease:- wire rope grease is a less viscous grease and anti-corrosive, it penetrates inside the wire rope.

Every ship has a lubricating chart for recommended grease types for particular work.

Note:

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://www.merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.