Uses of Chemicals in ship | Different machinery where chemicals are used onboard ship |

Chemicals play a crucial role in the safe and efficient operation of ships. From fuel additives to cleaning agents, lubricants to water treatment chemicals, a wide range of substances are used onboard vessels to ensure smooth sailing, prevent equipment damage, and maintain a safe and healthy environment. These chemicals are carefully selected, stored, and handled by trained professionals to meet the specific needs and requirements of different systems and operations on a ship. In this article, we will explore the diverse range of chemicals used on ships and their importance in supporting maritime operations.

Different machinery where chemicals are used onboard ships:

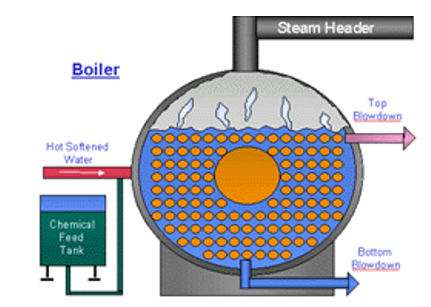

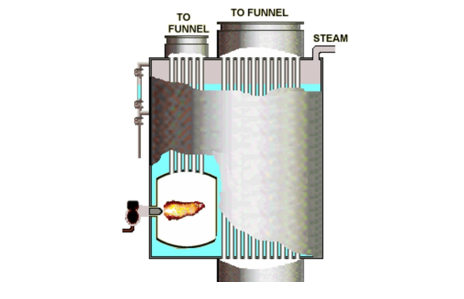

Boiler:

Chemicals are essential for maintaining the integrity of boilers and preventing corrosion. By adding chemicals to the boiler system, the formation of corrosive substances is minimized. This ensures that the boiler tubes remain in good condition, scaling is minimized, and efficient heat transfer takes place. With proper corrosion control, the efficiency and lifespan of the boiler are optimized, leading to reliable and long-lasting operation.

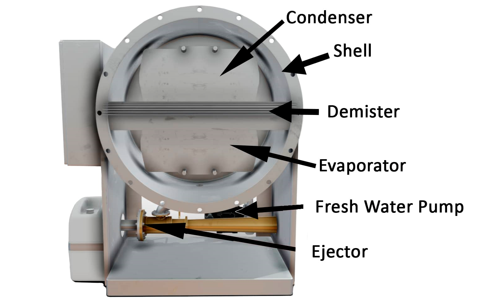

Fresh Water Generators:

Chemicals are employed in fresh water generators to prevent scaling on the evaporator side. Scaling occurs due to the accumulation of mineral deposits, which can hinder the performance of the fresh water generator. By adding appropriate chemicals, scaling is minimized, reducing the frequency of cleaning required. This ensures that the fresh water generator operates efficiently, providing a reliable source of fresh water for various onboard needs.

Main Engine Air Cooler:

Chemicals are utilized for the cleaning of main engine air coolers. Due to their large size, air coolers cannot be easily removed for cleaning. Therefore, onboard chemical cleaning of the air side is performed. Chemicals are applied to dissolve and remove accumulated dirt, debris, and deposits from the air cooler surfaces. This cleaning process helps maintain optimal heat transfer efficiency, ensuring the main engine operates at peak performance.

Exhaust Gas Boiler (EGB):

Chemicals are employed in the cleaning and maintenance of the exhaust gas boiler. The exhaust gas flowing through the EGB contains carbon deposits that can reduce heat transfer efficiency. Chemicals are injected into the EGB to react with these carbon deposits, lowering their melting point. This facilitates easier removal of the deposits during subsequent cleaning procedures. Soot blowing, which involves injecting high-pressure steam into the tube stacks, is performed to remove the loosened carbon deposits. Regular chemical cleaning and soot blowing help maintain the efficiency and reliability of the EGB.

Importance of proper chemical monitoring and procedures:

Proper monitoring of chemicals and adherence to correct procedures are crucial aspects of onboard ship routines. Diligently maintaining the correct quantity and quality of chemicals added to various systems ensures optimal performance and trouble-free operation of equipment. Regular checks, proper documentation, and adherence to recommended maintenance schedules are essential to prevent long-term problems.

By following these protocols, ship operators can mitigate issues, extend equipment lifespan, and ensure the smooth running of onboard machinery.

Conclusion:

Chemicals play a vital role in maintaining the efficient and reliable operation of various systems onboard ships. From preventing corrosion in boilers to minimizing scaling in fresh water generators, and from cleaning main engine air coolers to maintaining the performance of exhaust gas boilers, chemicals are crucial for ensuring the longevity and optimal performance of ship machinery.

Diligent monitoring, adherence to recommended procedures, and routine maintenance are essential to maximize the benefits of chemicals and ensure trouble-free operation at sea. By prioritizing the correct usage of chemicals, ship operators can significantly enhance the safety, efficiency, and longevity of their vessels.

Note:

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://www.merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.