Purifier on Ship? What are the different purifiers used onboard ship?

1:- What is Purifier?

- A purifier onboard a ship is a mechanical device that cleans and removes impurities from fluids such as fuel oil, lubricating oil, and water. The main types of cleaners commonly used on ships are centrifugal purifiers, coalescer purifiers, and oil-water separators.

- The primary functions of purifiers are to separate contaminants such as water, sludge, solid particles, and other impurities from these essential fluids to ensure their quality and usability.

1.1:- Significance of Purifier

- Ensuring the cleanliness of fuel and lubricating oil.

- Regular purification of oils and water prevents damage to engines and other machinery, reducing maintenance costs and extending their operational life.

- Clean fuel and clean water are vital for the safety of the ship and its crew. Contaminated fuel can lead to engine failures, while impure water can pose health risks.

- Ships must comply with international regulations regarding emissions and discharge of pollutants, effective purification systems help in meeting these regulatory requirements.

2:- Types of Purifiers on Ships

Ships use various types of purifiers to maintain the cleanliness and quality of fuel oil, lubricating oil, and water. The main types of purifiers onboard ships include:

- Centrifugal Purifiers

- Fuel oil purifiers are of two types:

- Fuel Oil Purifiers: These remove water, sludge, and other impurities from fuel oil. Clean fuel ensures better combustion and reduces engine wear.

- Lube Oil Purifiers: Designed to remove contaminants from lubricating oil, these purifiers help protect engine parts and extend the oil’s life.

- Coalescer Purifiers: These purifiers use coalescing elements to combine small water droplets into larger ones, making it easier to separate and remove them from fuel or lube oil.

- Hydrocyclone Purifier: Employing a high-speed rotating flow, hydrocyclone purifiers create centrifugal force to separate particles from fluids. These are less common but are used for specific applications.

- Electrostatic Purifiers: These purifiers use electrical charges to attract and remove fine particles from oil, providing supplementary purification to other methods.

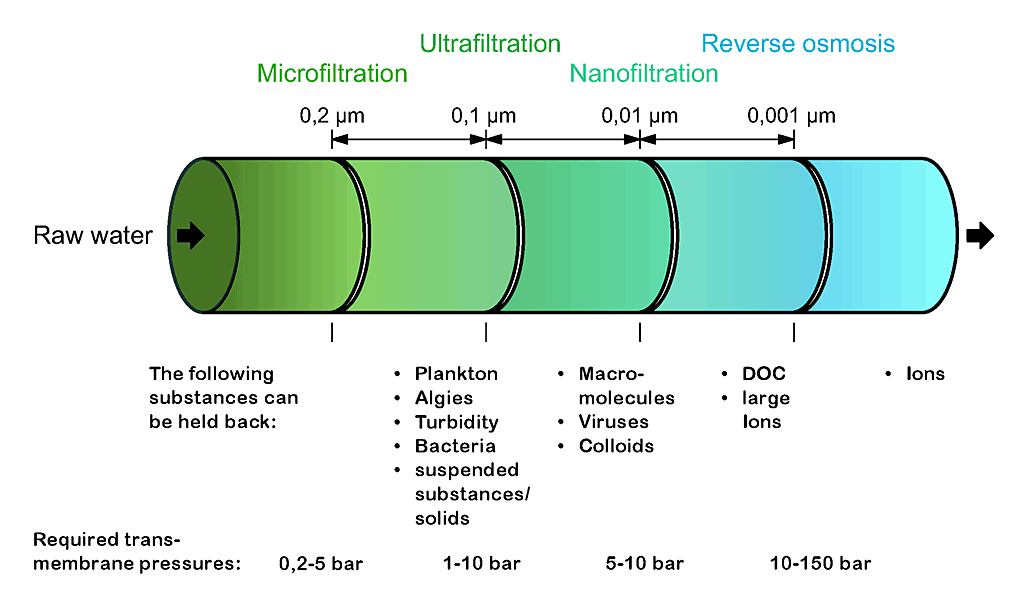

- Membrane Purifiers: Utilizing a semi-permeable membrane, these purifiers separate contaminants from water, commonly used in freshwater generation and wastewater treatment.

3:- What is a Centrifugal Purifier?

A centrifugal purifier is a device used onboard ships to clean and remove impurities from fluids, primarily fuel oil and lubricating oil. It utilizes centrifugal force to separate contaminants such as water, sludge, and solid particles based on their density differences. This method significantly enhances the efficiency of separation compared to gravity alone.

3.1:- Centrifugal Purifier Working Principle

Centrifugal purifiers operate on the principle of centrifugal force, which is a force that acts outward on a body moving around a center. This force is utilized to accelerate the separation of fluids and solids with different densities. Imagine a settling tank rotated on its side and spun at high speed; this creates a powerful centrifugal force that separates substances much more quickly than gravity.

3.2:- Working Principle of Cetrifugal Purifier

- Intake of Contaminated Oil: Contaminated oil is fed into the purifier through an inlet port.

- Rotation in the Bowl: The oil enters a rapidly rotating bowl, driven by a motor, generating high centrifugal force.

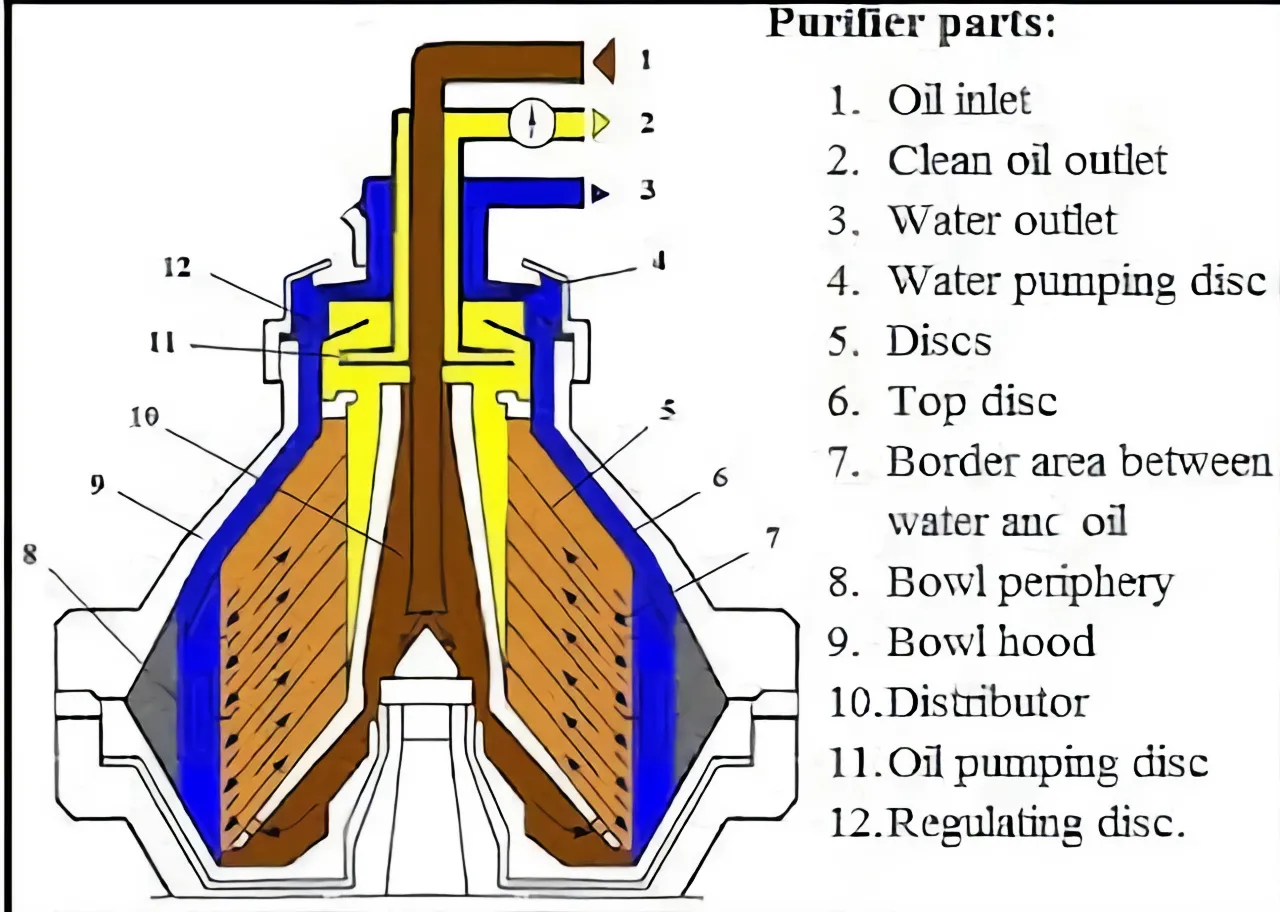

- Separation Process:

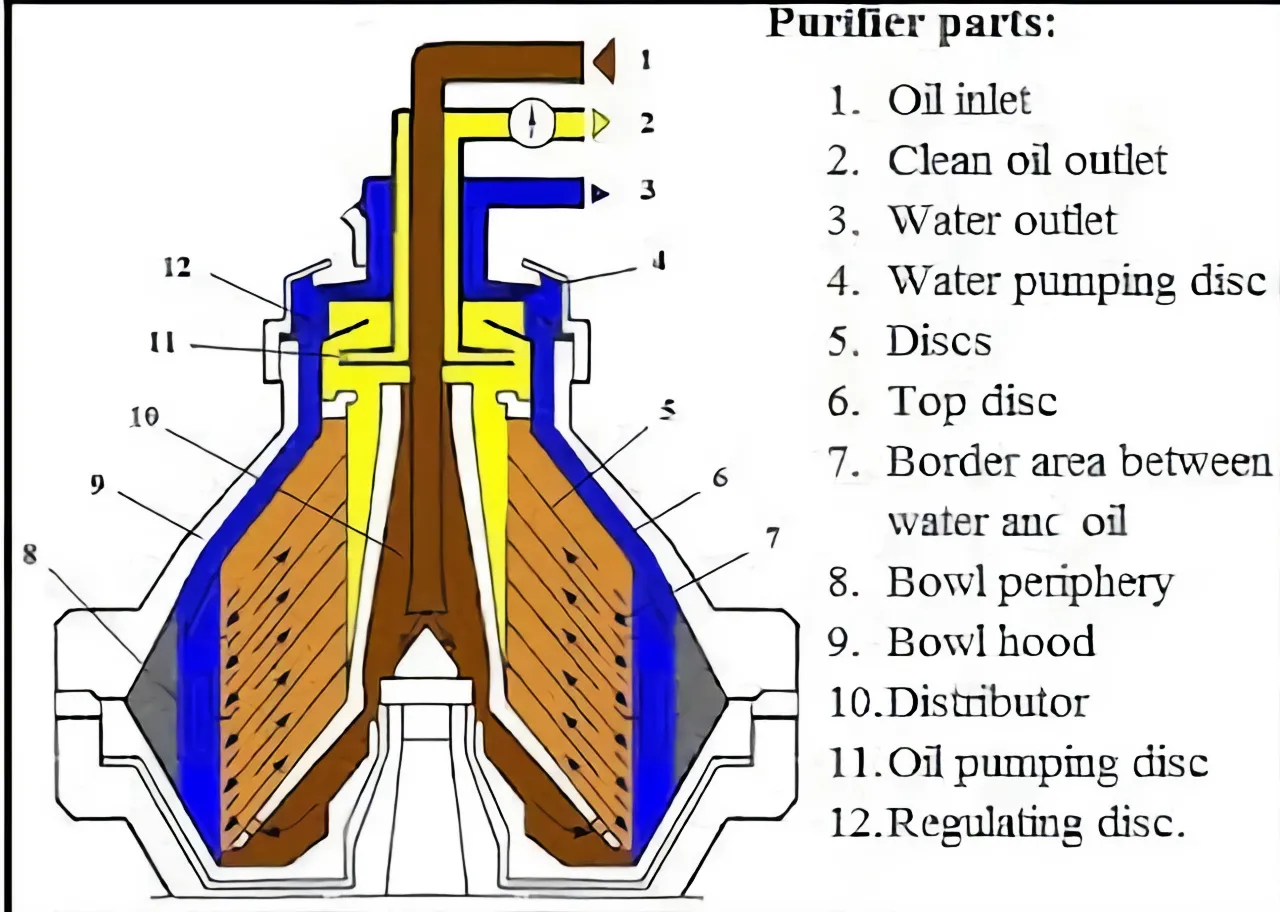

- Centrifugal Force: Heavier contaminants such as water and sludge move outward to the bowl’s periphery, while lighter clean oil stays closer to the center.

- Disc Stack: The bowl contains a stack of conical discs. The oil flows through these discs, which increases the surface area for separation, speeding up the process.

- Discharge of Separated Substances

- Sludge and Water Ejection: Heavier sludge and water collect at the outer edge of the bowl and are periodically or continuously ejected through designated ports.

- Clean Oil Collection: Purified oil is collected from the center of the bowl and exits through an outlet port.

- Control of Separation Interface: A gravity disc or ring dam is used to adjust the interface between the oil and water layers, ensuring efficient separation.

3.3:- Key Components of Centrifugal Purifier

- Rotating Bowl: The central component that spins at high speed to generate centrifugal force.

- Disc Stack: Conical discs inside the bowl that enhance separation efficiency.

- Inlet and Outlet Ports: Ports for feeding contaminated oil and collecting purified oil.

- Ejection Ports: Ports for discharging separated water and sludge.

- Gravity Disc/Ring Dam: Adjusts the separation interface for optimal efficiency.

3.4:- Important Things to Note

- Gravity Disc sets the location of the oil and water interface line. Correct size selection depends on separation temperature, oil density, and desired throughput.

- A Paring Disc is a stationary impeller that converts the rotating energy of the liquid into a pressure head.

- The water Washing technique is used to remove acids, salts, and impurities from oil. Water is injected before purifying, typically at a rate of 3-5% of the oil flow.

4:- What is a Coalescer Purifier?

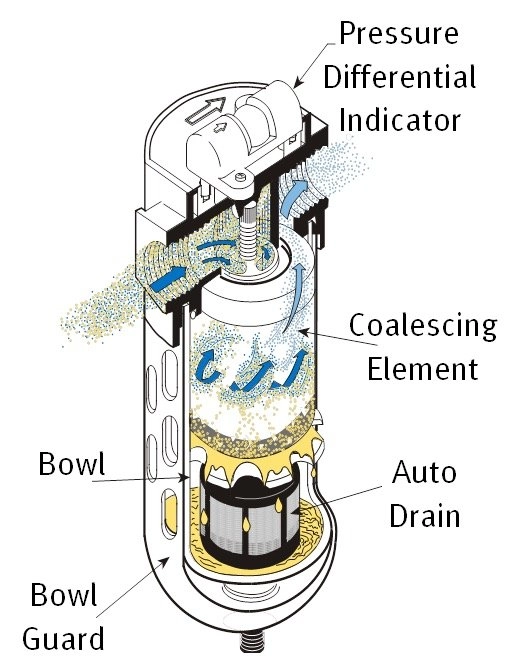

- Coalescer purifiers are a type of purification system used in various industries, including the maritime sector, to remove water and other contaminants from fluids such as fuel oil and lubricating oil.

- The principle behind coalescer purifiers involves the use of coalescing elements, typically in the form of special media or filters, to combine small water droplets dispersed in the oil into larger ones. These larger droplets are then easier to separate from the oil phase, facilitating their removal.

4.1:- Working Principle of Coalescer Purifier

- Contaminated fluid, which includes small water droplets dispersed in oil, enters the coalescer purifier.

- Coalescer purifiers contain specialized coalescing elements or media. These elements are designed to capture the dispersed water droplets as the fluid passes through them.

- As the fluid flows through the coalescing elements, the small water droplets come into contact with each other and begin to merge or coalesce.

- The coalescing elements provide a surface for the droplets to coalesce on, allowing them to combine and form larger droplets.

- Through the coalescence process, numerous small water droplets combine to form larger ones.

- These larger droplets are easier to separate from the oil phase due to their increased size and buoyancy.

- Once the water droplets have coalesced into larger ones, they separate more readily from the oil phase under the influence of gravity or centrifugal force.

- The separated water phase can then be removed from the purifier, leaving behind purified oil.

- The purified oil, now free from most water and contaminants, can be collected and used in various applications, such as fueling engines or lubricating machinery.

- The separated water phase may undergo further treatment or disposal, depending on regulatory requirements and environmental considerations.

4.2:- Advantages of Coalescer Purifiers

- Coalescer purifiers effectively remove water from fluids, ensuring improved quality and performance.

- By coalescing small water droplets into larger ones, these purifiers facilitate their separation from the oil phase, simplifying the purification process.

- Coalescer purifiers can be used in a wide range of applications and industries where water removal from fluids is essential.

5:- What is an Electrostatic Purifier?

An electrostatic purifier is a device used to remove particles and impurities from a gas or liquid stream using an electrostatic charge.

5.1:- Working Principle of Electrostatic Purifier

- The contaminated gas or liquid enters the electrostatic purifier.

- Inside the purifier, the particles in the stream pass through an electric field.

- This electric field charges the particles, giving them an electrostatic charge.

- The charged particles are attracted to oppositely charged collector plates within the purifier.

- This attraction causes the particles to adhere to the collector plates, removing them from the stream.

- After passing through the collector plates, the purified gas or liquid stream exits the purifier, now free from most impurities.

For cleaning and maintenance of the electrostatic purifier, the collector plates need to be cleaned to remove the accumulated particles.

6:- What is a Membrane Purifier?

A membrane purifier is a type of filtration system that uses a semi-permeable membrane to separate impurities from a fluid, typically water.

6.1:- Working Principle of Membrane Purifier

- Dirty water enters the membrane purifier.

- The purifier has a special membrane that lets water pass through but blocks impurities like dirt, bacteria, and chemicals.

- As the water flows through the membrane, impurities get trapped on one side while clean water passes through to the other side.

- The clean water is collected and ready for use.

7:- Difference between Purifier, Filter and Separator

| Aspect | Purifier | Filter | Separator |

| Function | Cleans fluids using centrifugal force | Removes solid particles using a porous medium | Separates immiscible liquids or solids using gravity, coalescence, or centrifugal force |

| Working Principle | Centrifugal force separates impurities based on density | Fluid passes through a medium that traps particles | Various methods (gravity, coalescence, centrifugal force) to separate components |

| Types of Contaminants Removed | Water and solid impurities from oils | Solid particles from fluids | Immiscible liquids (e.g., oil and water) and solids from liquids |

| Common Applications | Fuel and lubricating oil purification | Fuel and oil filtration, air filtration | Bilge water treatment, oil-water separation, fuel and oil treatment |

FAQs Related to Purifier.

1:- What is a Bowl Purifier?

- A bowl purifier is a type of machine used on ships to clean liquids like fuel or oil. It spins rapidly, using centrifugal force to separate dirt and water from the liquid. The clean liquid is kept in the center while the separated dirt and water are removed from the edges.

2:- What equipment does MARPOL mandate ships to have to ensure clean oil discharge into the sea?

- MARPOL requires ships to have efficient oil filtering equipment, including purifiers, to ensure that only clean oil is discharged into the sea, and ships must maintain documentation and records to demonstrate compliance.

3:- What is the purpose of a purifier onboard ships?

- Purifiers are essential onboard ships to clean and remove impurities from fluids like fuel oil, lubricating oil, and water.

- Purifiers ensure the cleanliness of fuel and lubricating oil, preventing damage to engines and machinery, reducing maintenance costs, and extending their operational life.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.