Pump Automatic Changeover System in ship

In ships, the Pump Automatic Changeover system is used to ensure that essential services such as fire-fighting pumps, bilge, ballast, and fuel oil pumps continue to operate even if one pump or system fails or requires maintenance. The system automatically switches between different pumps or systems when certain conditions are met, ensuring the continuous availability of the required service.

What safeties are there in case if an important pump stops accidentally or fails?

Automatic changeover systems can switch between different pumps or systems if one of them fails or is unable to operate properly.

What causes Pump Automatic Changeover?

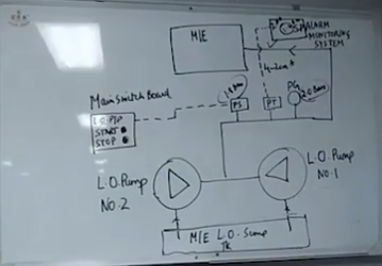

During night time, the Engine Control Room operates automatically as there are no personnel present. In the event of an essential pump malfunctioning, a backup system is available to take over its function. The lubrication system of the main engine is crucial for its proper operation and must be continuously maintained. If the lubrication system fails, it can cause damage to the bearings, resulting in significant losses for the owner. Hence, a Pump Auto Changeover is necessary to ensure continuous lubrication and prevent any potential damages.

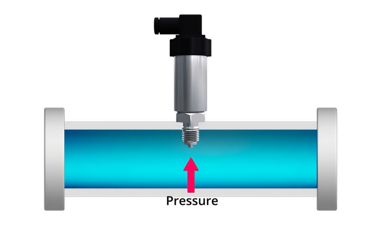

In the event of the lube oil pump ceasing to function, an alarm will sound in the Chief Engineer’s cabin, and the standby pump should activate automatically to maintain the pressure of 2 bar. A pressure gauge is installed to indicate the pressure level, and a pressure transducer is fitted to convert the actual pressure into a current signal (4-20mAps) which is then converted back to pressure to display the reading in the Engine Control Room. The pressure transmitter sends the signal to display the pressure level of 2 bar in the ECR.

A set point of 1.8 bar is established to trigger an alarm through the Alarm Monitoring System if the pressure falls below the set point, alerting the engineers to take necessary corrective action. As the duty engineer may not be immediately available in the ECR, a pressure switch is installed to activate the Pump Auto Changeover and use the standby pump during the transition period.

Upon the Number 1 lube oil pump ceasing to function and a subsequent drop in pressure, an alarm will be triggered at the set point of 1.8 bar. A pressure switch is installed to receive the signal at the same set point, activating the Number 2 lube oil pump to start automatically and take over the function of the failed pump.

Note:

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://www.merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.