Cast Iron and its properties

What is Cast Iron?

Cast iron is a group of iron-carbon alloys with a carbon content greater than 2%. It is a versatile material that has been used for centuries in a variety of applications, from cookware to construction. Cast iron is valued for its high strength, durability, and ability to retain heat, among other properties.

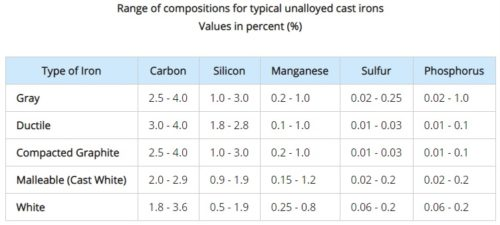

Composition of Cast Iron

Cast iron is composed of iron, carbon, and silicon, with additional elements such as manganese, sulphur, and phosphorus added to modify its properties. The carbon content of cast iron is higher than that of steel, which typically has a carbon content of 0.2% to 2.1%.

The higher carbon content in cast iron contributes to its unique properties, including its ability to retain heat and its superior strength and durability. However, it also makes cast iron more brittle than steel, which can lead to cracking or breaking under stress.

The exact composition of cast iron can vary depending on the specific type of cast iron and the intended application. In addition to carbon and silicon, some of the common alloying elements added to cast iron include:

Manganese: Manganese is added to improve the strength and hardness of cast iron.

Sulphur: Sulphur is added to improve machinability, but it can also make the cast iron more brittle.

Phosphorus: Phosphorus is added to improve fluidity and castability, but it can also make the cast iron more brittle.

Nickel: Nickel is added to improve toughness and corrosion resistance.

Chromium: Chromium is added to improve wear resistance and corrosion resistance.

How is it made?

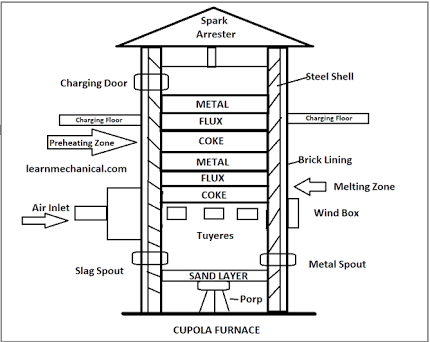

Cast iron is produced by re-melting pig iron in a cupola(a small type of blast furnace) wherein the composition of the iron is suitably adjusted.

Fast cooling produces a fine grain structure while slow cooling produces a coarse grain structure, uneven cooling produces poor quality cast iron.

Types of Cast Iron

There are several different types of cast iron, each with its own unique properties and applications. The most common types of cast iron include:

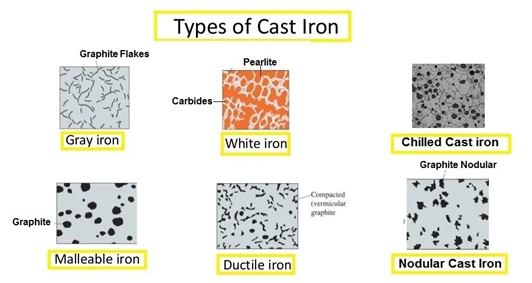

Gray Cast Iron: Gray iron is the most commonly used type of cast iron. It is named for its grey colour, which is due to the graphite flakes that are present in the material. Gray iron is easy to cast and machine, making it ideal for a wide range of applications, including engine blocks, pipes, and cookware.

Ductile Cast Iron: Ductile iron, also known as nodular cast iron is a type of cast iron that has been treated with small amounts of magnesium or cerium to cause the graphite to form in a spherical shape. This gives ductile iron its unique properties, including higher tensile strength, toughness, and ductility than grey iron. Ductile iron is commonly used for applications such as water pipes, automotive components, and gears.

White Cast Iron: White iron is a hard, brittle material that is often used for its abrasion resistance. It is named for its white colour, which is due to the absence of graphite. White iron is often used in applications such as grinding balls, liners for mining equipment, and pump impellers.

Malleable Cast Iron: Malleable iron is a type of cast iron that has been heat-treated to make it more ductile and less brittle. This process involves heating the iron to a high temperature and then cooling it slowly. Malleable iron is often used for applications such as pipe fittings, gears, and hand tools.

Properties of Cast Iron

Cast iron has several unique properties that make it ideal for a variety of applications. Some of the key properties of cast iron include:

- High Strength: Cast iron is stronger than many other materials, including steel, due to its high carbon content. This makes it ideal for applications that require a high degree of strength, such as engine blocks and machinery components.

- Durability: Cast iron is highly resistant to wear and tear, making it ideal for applications that involve high levels of abrasion or impact, such as mining equipment or pump impellers.

- Heat Retention: Cast iron has excellent heat retention properties, which make it ideal for use in cookware. Cast iron cookware can retain heat for a long time, allowing food to cook evenly and thoroughly.

- Machinability: Cast iron is relatively easy to machine, making it ideal for applications that require complex shapes or precise tolerances.

- Corrosion Resistance: Cast iron is highly resistant to corrosion, making it ideal for outdoor applications or applications that involve exposure to harsh chemicals.

- Damping Capacity: Cast iron has excellent damping capacity, which means it can absorb vibrations and reduce noise. This property makes it ideal for applications such as machinery beds and engine blocks.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.