Air Compressor in Ships

1:- Introduction

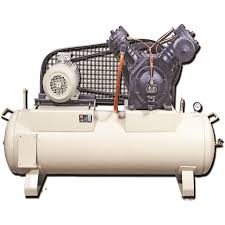

Air compressors on ships fill multiple necessities, from airing pneumatic instruments to providing air for vital systems. Now, let’s start with the very basics of air compressors on ships, which are just compressors. We will look at their functions, types, maintenance, and safety measures.

2:- Air Compressor in Ship

- Compressors with big power are similar to pumps working with high pressure; they take in air from the surroundings and, as a result, compress it to a higher pressure level.

- This happens with the help of the compressor, which sucks in the ambient air through an inlet valve. Within the engine, the air is pressurized using either pistons, rotors, or impellers, depending on the type of compressor.

- While the compressor mechanism translates, it decreases the air volume, and this, in turn, causes the air molecules to become closer and, eventually, the pressure level to increase.

- Then, the air being compressed is stored in the tanks, which are called air receivers, where the air is held down to the specified pressure until it gets used. When a tool or piece of equipment needs air, a valve opens, enabling the compressed air to flow out of the tank and through the connected hoses or pipes to the desired application.

Check out Visionary Course to learn everything about Air Compressor in Ship.

3:- Functions of Air Compressors on Ships

The air compressors on board ships (which in turn power functional uses and operations of the ships) are an indispensable part of the maritime sector needed for the operation of ships. Their primary role is to provide compressed air, which is utilized for various purposes.

- Powering Pneumatic Tools: With an air compressor on board that provides high-pressure air to operate the range of pneumatic tools, including drills, wrenches, and paint sprayers, the ship’s personnel can address minor maintenance, repair, and construction tasks during the voyage.

- Supplying Air for Vital Systems: They send the compressed air to the critical ship systems like the starting air system for main and auxiliary engines, pneumatic control systems, and air-driven pumps, which are the main and maneuvering systems of the vessel.

- Supporting Safety Equipment: Air compressors are responsible for environmental safety as they provide the air needed to power breathing equipment and firefighting gear, which are crucial for disaster response and the protection of crew members who might get into trouble in hazardous atmospheres.

Click here to learn about the complete use of air compressor in ships.

4:- Types of Air Compressors

4.1:- Reciprocating Type Air Compressor

These compressors operate in the same way as a car engine. One of the most devastating forms of natural disasters is a hurricane. They have pistons that move up and down, which compresses the air around them. They are just as good and are also used for many other shipwork tasks.

4.2:- Screw Type Compressor

These compressors employ two screws that turn together to compact air. They are efficient and can work non-stop, which makes them excel at those high-intensity activities.

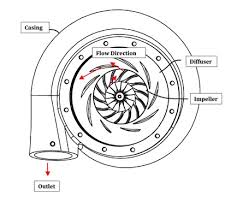

4.3:- Centrifugal Air Compressor

The compressors that this machine utilizes use a spinning wheel as their mode of operation. Pressure is generated through atmospheric pressure outside of the wheel. They are the main engines in the ships and are used for starting the engines.

Also check out multiple stages of air compressor with our dedicated blog on multistage air compressor.

5:- Maintenance of Air Compressor on Ship

- Regular Inspection: Check for leaks, worn-out parts, and proper oil to ascertain that the compressor is quick-moving.

- Cleaning Air Filters: Clean or replace the air filters regularly, and dust and debris won’t damage the compressor’s internal parts.

- Lubrication: Provided the internal parts are well-oiled to prevent unnecessary friction and enhance their performance.

- Draining Condensate: In regular periods, the condensate should be drained from the air compressor to impede corrosion and maintain healthy air.

- Tightening Connections: Look for and close the leaks in the connections to avoid air loss and make sure that the vehicle will run efficiently.

- Monitoring Temperature and Pressure: Set a prediction schedule and track temperature and pressure levels to detect any abnormalities that may be a precursor to any future problems.

- Scheduled Maintenance: Follow after-manufacturing guidelines for planned tasks such as oil changes, filter replacements, and checkups.

- Training Personnel: Train the crew members on basic maintenance procedures and safety protocols so that the air compressor is properly cared for and operated safely.

6:- Air Compressor Safeties

6.1:- Alarms in Air Compressor

- High Discharge Temperature Alarm

- Indicates the high temperature of the existing compressed air from the compressor and is a sign of inefficient operation.

- Caused by Improper cooling (cooling insufficient), overloading (overloaded), or lack of grease (grease insufficient).

- Low Oil Pressure Alarm:

- Under pressure in the crankcase means that the compressor leaks oil.

- Caused by low-level or leaking oil or a malfunctioning oil pump.

- High Air Discharge Pressure Alarm

- The gauge shows up on leaving the compressor unit the relative pressure is high which is compressed air turning into larger volume air.

- A potential problem might include clogging of the main discharge line, a bad pressure regulator, or a high power requirement.

- Motor Overload Alarm

- Shows that the compressor electric motor is overloading with current.

- Caused by overloading, motor failure, or extra drag force.

6.2:- Trips in Air Compressor

- High Discharge Temperature Trip

- A hot trigger fires when the discharge temperature is too high for use.

- Saves the compressors from the heat of the components.

- Low Oil Pressure Trip

- Sets in motion when oil pressure drops below safe standards.

- It prevents damage due to poor lubrication.

- High Air Discharge Pressure Trip

- It energizes when the pressure discharge outreach ensures safety.

- It prevents downstream equipment from being overdriven.

- Motor Overload Trip

- Activates when the power supply drawn by the compressor’s motor exceeds its inherent threshold levels.

- The system does not allow the engine to get overheated or damaged, thanks to it.

7:- Conclusion

Air compressors are the vital ones for the ship, they provide different services that are very important for the ship to be in good condition and safe. Knowing their fundamental principles , types, maintenance components, and safety regulations can be extremely useful for successful application in marine life. Adopting preventative measures and security standards for air compressors would keep this equipment to uphold the perfect marine environment at sea.

8:- Air Compressor Frequently Asked Questions

An air compressor is a device that tunes air pressure, pushed by medium force, for tools and systems on board ships.

Compressors perform as an air source for pneumatic tools, controlling shipping systems, or life support equipment supplies like breathing apparatus.

It takes in air from the surroundings and compresses it, giving it more power. The air gets squeezed into the storage tank for later usage.

There are three main types: reciprocating, rotary screw, and centrifugal compressors, each of which has its own way of compressing air.

While you ought to take capacity requirements, space availability, suitability of power source, and reliability considerations into account when choosing a ship air compressor unit.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.