Safeties in a Refrigeration system used in ship

Refrigeration systems contain several safeties to protect against equipment failure, leaks, and other potential hazards. Here are some of the key safety features typically found in refrigeration systems:

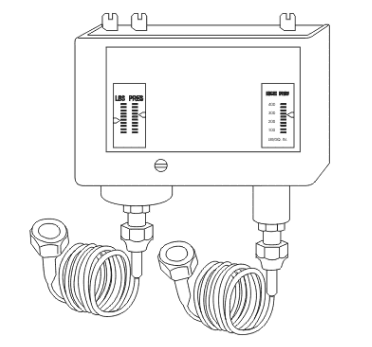

Low pressure (Lp) cut out:

Low pressure cut-off is fitted before the suction port of the compressor and it is used for safety purposes when the suction pressure comes down the cut-off stops the compressor and when pressure rises back the compressor will start again.

High pressure (HP) cut-off:

The high-pressure cut-off is fitted after the delivery port. It is used to save the high-pressure line, when the pressure becomes too high it will stop the compressor.

Suction and delivery pressure gauge:-

It is used for measuring the pressure in the suction side and delivery side of the compressor.

Pressure Relief Valves (PRV’s):

These valves are designed to release pressure in the refrigeration system if it exceeds a certain level, preventing the system from bursting. PRV’s are typically set to open at a pressure slightly above the design pressure of the system.

Oil Pressure Safety Switch:

This switch is designed to shut off the compressor if the oil pressure drops below a certain level, indicating a potential issue with the lubrication system.

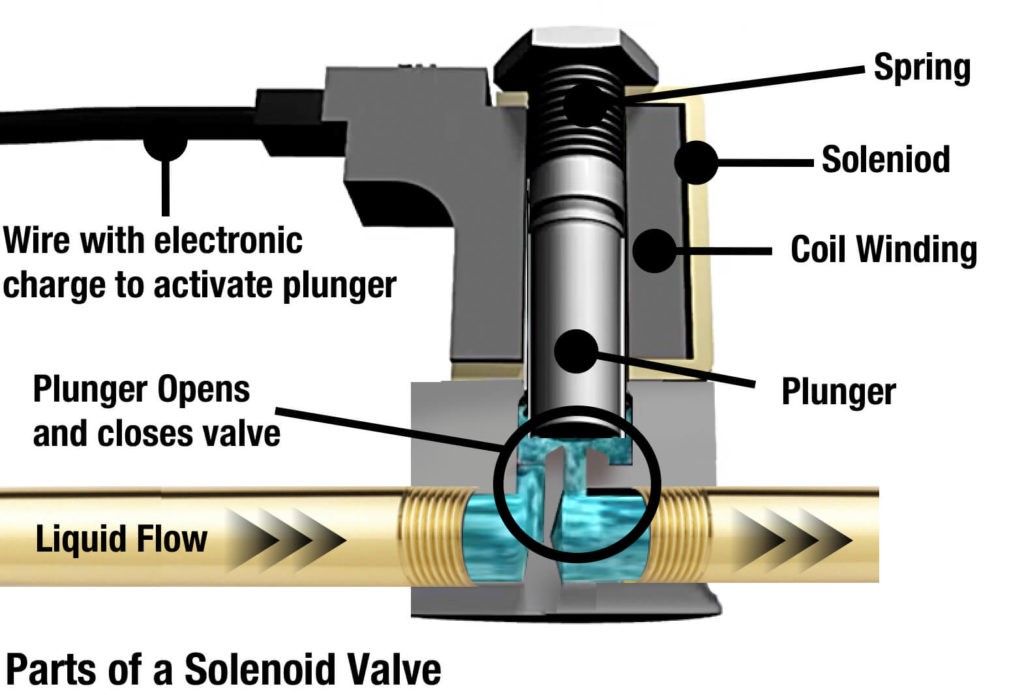

Liquid Line Solenoid Valve:

This valve is typically installed in the liquid line of the refrigeration system and is designed to shut off the flow of refrigerant in the event of a power outage or other system failure.

Sight Glass:

This glass is typically installed in the liquid line and allows the technician to visually inspect the refrigerant for any signs of moisture, which can indicate a potential leak.

Low Ambient Temperature Control:

This control is designed to shut off the compressor if the ambient temperature drops below a certain level, preventing the system from operating at a temperature that could damage the compressor or other components.

These safety features are essential for ensuring the safe and reliable operation of refrigeration systems. Regular maintenance and inspection of these features are crucial to identify any potential issues and prevent equipment failure and hazards.

Note:

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://www.merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.