Working of the refrigeration system (VCRS) in ship | Working of the sensing bulb and thermostatic expansion valve|

1:- Process of Refrigerator in Ship

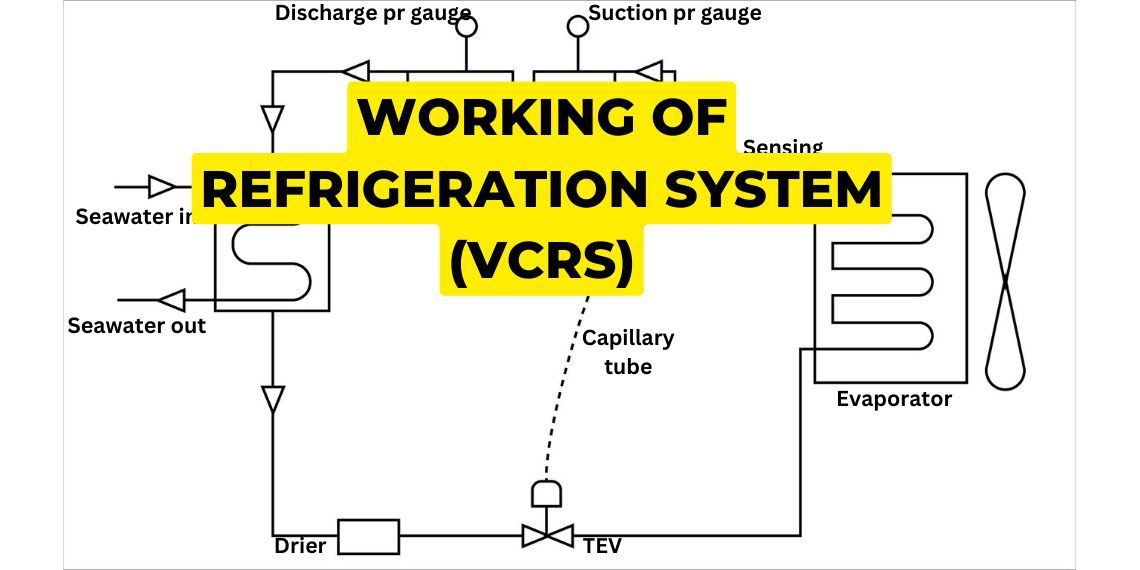

Four different processes are involved in a refrigeration system’s main components.

- In compressor-isentropic compression.

- In evaporator – Isobaric heat rejection/ condensation.

- In the thermostatic expansion valve – Isenthalpic expansion.

- In evaporator – Isobaric heat absorption.

2:- Working of the Refrigeration system (VCRS)

- The air inside the room is sucked into the evaporator and it exchanges the heat with the refrigerant which allows the air in the room to cool down and this air is circulated continuously. This heat converts the refrigerant into a gas or vapor state. This low-temperature low-pressure super-heated refrigerant vapor is sucked by the compressor and compressed to a high-temperature and high-pressure super-heated vapor.

- After compression, this gas goes into the condenser to release the heat of the gas and turns into liquid. The condenser is a type of exchanger which has seawater lines in it. At first, when the refrigerant goes into the condenser, the temp drops slightly as the refrigerant is super-heated, and then the refrigerant changes into a slightly low-temperature liquid refrigerant. After that, this high-pressure refrigerant fluid goes through the drier, and all moisture will be absorbed.

- When this high-pressure fluid goes through the thermostatic expansion valve orifice its pressure suddenly drops due to its volume increases, refrigerant drops to a very low temp pressure and it becomes a mixture of liquid plus vapor refrigerant and then it goes into the evaporator.

- At the initial point of the evaporator pipe, the refrigerant temperature is low but the temperature continuously increases from absorbing the heat and converting refrigerant liquid to a gas by the latent heat of the vaporization process. After the evaporator sensing bulb senses the temperature of vapor to control the thermostatic expansion valve regulator. When the gas temperature is very high it means more refrigerant is required in the evaporator for cooling and the whole cycle continues.

- Two pressure zones are present in the total cycle. From the delivery side of the compressor to the thermostatic expansion valve, the orifice is a high-pressure line after the orifice to the suction of the compressor is the low-pressure line.

3:- Procedure for Charging Refrigeration System in Ship

The charging procedure can differ slightly depending on the refrigerant type and the specific system design. However, in general, these are the stages:

3.1:- Preparation and Safety of Ship Refrigeration System

- Personal Protective Equipment (PPE): Always observe PPE requirements such as wearing safety goggles, gloves, and protective clothing.

- Ventilation: Ensure proper ventilation of the area to avoid refrigerant vapor accumulation.

- System Isolation: Separate it from other machinery that belongs to a ship so as not to cause any accidental action while being charged.

- Leak Check: Carry out a detailed leak check across all parts of the system using either a gas or soap solution leak detector and fix any leakage before you proceed.

- Evacuation: Remove air and moisture within the system with the use of a vacuum pump. This is very crucial since contaminated systems do not run properly when recharged.

3.2:- Connection and Measurement of Refrigeration System in Ship:

- Manifold Gauge Set: Connect a manifold gauge set with a high-pressure service port or low-pressure service port of the system. These allow you to monitor pressures during charging.

- Refrigerant Cylinder: Use a charging hose to connect the refrigerant cylinder to the manifold by ensuring that the cylinder valve is blocked off.

3.3:- Charging Process for Refrigeration System on Ship:

- Weights Charging: The majority of on-board ship systems require the use of weight charging. We could measure the weight of the refrigerant cylinder before and after recharging.

- Vapor or Liquid Charging: Depending on the type of refrigerant and design of a system, charging can be done in vapor form through the low-pressure side or liquid form through the high-pressure side. Consult the system’s manual to find out.

- Gradual Charging: Slowly open the cylinder valve and allow refrigerant to enter the system gradually while watching the pressure gauges.

- Target Pressures: For proper target pressures (suction and discharge) on an operating temperature, reference to the system’s specifications is required.

3.4:- Verification And Adjustment of Refrigeration System in Ship:

- Leak Check: After charging, make another leak check to ensure that no leaks have resulted from it.

- System Operation: Switch on for some time monitoring pressures, temperatures, and overall performance

- Refrigerant Charge Adjustment: If it’s not up to spec adjust refrigerant charge whatever it takes This may involve incrementing or decrementing minute amounts of refrigerant.

4:- What is Refrigerant Recovery?

Refrigerant recovery is the process of extracting refrigerant from a system, usually during maintenance, repair, or equipment decommissioning. It’s an important step in preventing the release of harmful refrigerants into the atmosphere that can cause ozone depletion and climate change.

4.1:- Methods for Refrigerant Recovery:

There are two primary methods of recovering refrigerants:

- Active Recovery:

- Process: Active recovery involves the use of specific machines (recovery units) to pump out refrigerants from systems and deposit them in a recovery cylinder.

- Advantages: Faster, more efficient than passive recovery, suitable for larger systems, recovers refrigerants even from low-pressure systems.

- Equipment: Requires a dedicated recovery unit and hoses as well as gauges.

- Passive Recovery

- Process: Passive recovery works by utilizing the difference in pressure between the system and the location where it is recovered. High-pressure systems then convey gases to lower-pressure cylinders.

- Advantages: Simpler; often cheaper than active recovery; compatible with smaller units

- Limitations: Slower than active recovery, may not recover all refrigerants present in the system especially when there is low system pressure.

5:- What is Refrigerant Recycling?

Cleaning and purifying recovered refrigerant to get rid of impurities like moisture, oil, and dirt is referred to as refrigerant recycling. This is done to ensure that the refrigerant meets the prescribed purity standards by such organizations as the Air-Conditioning, Heating, and Refrigeration Institute (AHRI).

5.1:- Process of Recycling:

- The oil separator runs over the collected coolant to get rid of any oils present in the system.

- Filtering: Then the coolant has to go through a filter process for it to remove all solid contaminants.

- Dehydration: The coolant has to pass a dehydrator stage which removes every trace of water in it.

- After distillation, it may have some further refining done on it depending on the type of coolant.

6:- Working of Sensing Bulb

In the refrigeration system, the sensing bulb is fitted at the discharge line of the evaporator which senses the temp of the refrigerant coming from the evaporator. The sensing bulb has the same refrigerant in a confined space that flows in the main system when the degree of superheat of the refrigerant is more than the sensing bulb senses it. The refrigerant in the sensing bulb vapourises which increases the pressure in it and as we know the fluid flows from high pressure to low pressure region. The refrigerant in the sensing bulb flows through the capillary tube to the Thermostatic Expansion Valve.

7:- Working of Thermostatic Expansion Valve

The components of a thermostatic expansion valve are:

- The diaphragm

- The pin

- The orifice

- The poppet valve

- The spring

7.1:- When the Degree of Superheat of Refrigerant is Higher:

If the superheat of the refrigerant is more than the pressure in the sensing bulb will increase and the refrigerant will flow towards the TEV through the capillary tube and will hit the diaphragm. The diaphragm will push the pin situated below, and the pin will push the poppet valve and the spring, when the poppet valve goes down it will open the orifice, and the flow of refrigerant increases.

7.2:- When the Degree of Superheat of Refrigerant is Less:

If the superheat of the refrigerant is less then the pressure will decrease in the sensing bulb and the spring in the TEV will push the poppet valve up due to which the orifice will close which will restrict the flow of refrigerant into the evaporator.

To learn about the complete working of the Thermostatic Expansion Valve, CLICK HERE

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.

Can you give pdf film working principle of marine refrigerator System

You will get all the detailed lectures on marine refrigeration system in the Dreamer Package. You can check it out for the better understanding of refrigeration system.