Steam Engine

The steam engine stands as a monumental invention that fueled the Industrial Revolution and transformed the world. Developed in the 18th century, the steam engine revolutionized transportation, powered factories, and drove the progress of modern civilization. In this blog post, we will explore the fascinating history, workings, and impact of the steam engine, shedding light on its significant contributions to various industries.

Origins of the Steam Engine

The steam engine owes its inception to the brilliant mind of Thomas Newcomen, an English inventor who developed the first practical steam engine in 1712. Newcomen’s engine, known as the atmospheric engine, utilized steam pressure to create a vacuum that operated a piston. Although crude in design, this early steam engine laid the foundation for further advancements.

Who Invented the Steam Engine?

The steam engine was invented by several individuals throughout history, with each contributing to its development and improvement. The first practical steam engine was created by Thomas Newcomen, an English inventor, in 1712. Newcomen’s invention, known as the atmospheric engine, utilized steam pressure to create a vacuum and operate a piston. Although Newcomen’s engine was a significant breakthrough, it had limitations in terms of efficiency.

James Watt, a Scottish engineer, made significant improvements to the steam engine in the late 18th century. He introduced the separate condenser, a key innovation that increased efficiency by condensing steam separately from the cylinder, reducing energy waste and improving power output. Watt’s improvements made steam engines more reliable and cost-effective, which led to their widespread adoption in various industries.

While Newcomen and Watt played pivotal roles in the development of the steam engine, it is important to note that the concept of harnessing steam power had been explored by earlier inventors and engineers, including Hero of Alexandria in the first century and Thomas Savery in the late 17th century. These early contributions laid the groundwork for subsequent inventors to refine and enhance steam engine technology.

James Watt and the Improvement of the Steam Engine

It was James Watt who significantly enhanced the steam engine’s efficiency and practicality. In the late 18th century, Watt introduced the separate condenser, which allowed the steam to be condensed separately, reducing energy waste and increasing power output. Watt’s improvements made steam engines more cost-effective and reliable, leading to their widespread adoption in various industries.

The Industrial Revolution and the Steam Engine

The steam engine played a pivotal role in the Industrial Revolution, a period of rapid industrialization and technological advancement. Prior to the steam engine, most manufacturing processes relied on manual labor and animal power. However, the steam engine provided a reliable and consistent source of power, enabling factories to increase production and scale their operations exponentially. This development marked a turning point in human history, propelling society towards modernization.

Steam Engine and Transportation

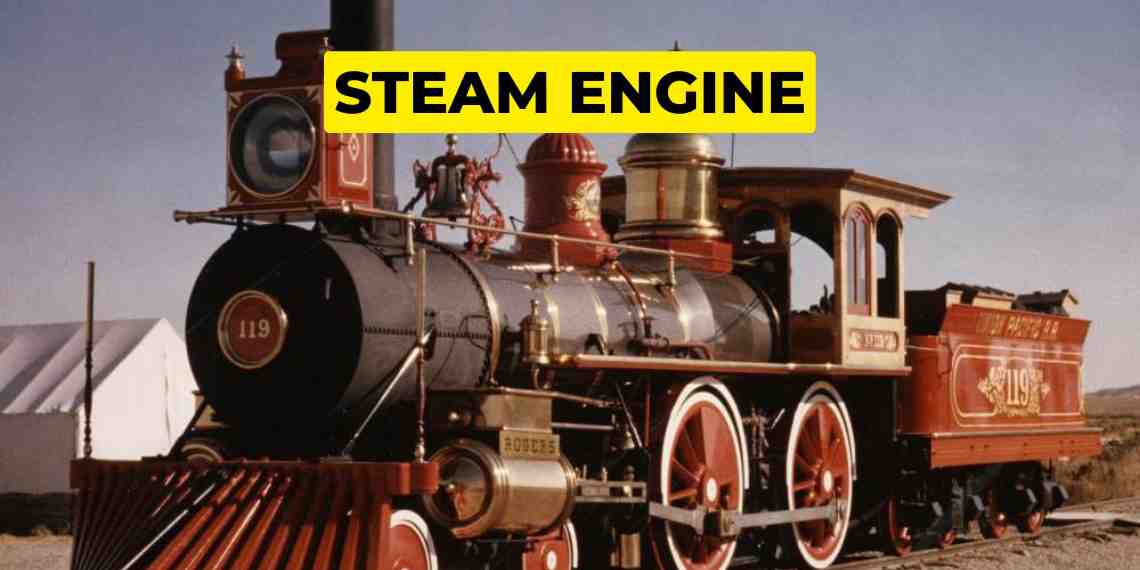

The steam engine’s impact on transportation was monumental. It revolutionized both land and sea travel, connecting distant regions and transforming the concept of mobility. In the early 19th century, steam-powered locomotives emerged, revolutionizing railway transportation. The locomotive, with its powerful steam engine, could pull heavy loads over long distances at unprecedented speeds. This breakthrough not only facilitated the transportation of goods but also revolutionized passenger travel, opening up new opportunities for trade and commerce.

Similarly, steam-powered ships or steamboats transformed the maritime industry. Prior to their advent, ships were dependent on unpredictable winds, making voyages time-consuming and unreliable. With steam engines, ships could navigate more efficiently, overcoming the limitations of wind-powered vessels. Steam-powered ships greatly accelerated global trade, facilitating the transportation of goods and people across vast distances.

Steam Engine Applications in Power Generation

Besides transportation, steam engines found extensive use in power generation. The development of stationary steam engines allowed factories and mills to harness steam power on-site. These engines provided a continuous source of power, replacing waterwheels and animal-driven machinery. The adoption of steam engines in factories revolutionized production processes, increasing output and efficiency. The ability to generate mechanical power from steam also contributed to the rise of heavy industries such as iron and steel production, further fueling industrial growth.

Evolution of the Steam Engine

The steam engine’s impact persisted long after its initial introduction. Its success paved the way for subsequent advancements, including the development of more powerful engines, the introduction of high-pressure steam, and the eventual adoption of steam turbines. The principles established by the steam engine also influenced the design of internal combustion engines, which dominate modern transportation.

However, as technology progressed, steam engines gradually declined in popularity. The emergence of electric power and internal combustion engines gradually replaced steam engines in various applications. Nonetheless, the steam engine’s legacy endures, reminding us of its pivotal role in shaping the modern world.

Why need Steam Engine?

- Industrial Revolution: Revolutionized factories and enabled mass production.

- Transportation: Revolutionized land and sea travel, facilitating trade and connectivity.

- Power Generation: Provided reliable and continuous power for industries.

- Mining and Extraction: Improved efficiency and safety in mining operations.

- Agricultural Advances: Increased farming efficiency and crop yields.

- Exploration and Colonization: Enabled long-distance travel and colonization.

Types of Steam Engine

There are several types of steam engines that have been developed over time. Here are some notable types:

- Reciprocating Steam Engine: The reciprocating steam engine is the most common type of steam engine. It consists of a cylinder with a piston that moves back and forth, driven by the force of expanding steam. This type of engine was widely used in various applications, including transportation and power generation.

- Steam Turbine: A steam turbine is a rotary engine that converts the energy of high-pressure steam into mechanical power. It operates on the principle of a rotating turbine rotor, which is driven by the force of steam jets. Steam turbines are highly efficient and are commonly used in power plants for electricity generation.

- Steam Locomotive: A steam locomotive is a type of steam engine specifically designed for railway transportation. It typically consists of a reciprocating steam engine connected to wheels and a boiler to generate steam. Steam locomotives were widely used in the 19th and early 20th centuries before being largely replaced by diesel and electric locomotives.

- Steamship Engine: Steamship engines, also known as marine steam engines, were specifically designed for powering steamships and steamboats. They were crucial in revolutionizing maritime transportation. Steamship engines varied in design and included both reciprocating engines and steam turbines.

- Stationary Steam Engine: Stationary steam engines were developed for stationary applications, such as powering factories, mills, and industrial machinery. They provided a continuous source of power and were often large and stationary installations.

- Steam Engine with Multiple Expansions: Multiple expansion steam engines, also known as compound engines, were developed to increase efficiency. These engines had multiple cylinders of different sizes, where steam expanded successively in each cylinder, extracting more work from the steam before it was exhausted. Multiple expansion engines were commonly used in large power plants and ships.

- Uniflow Steam Engine: The uniflow steam engine is a type of reciprocating engine where the steam flows in one direction through the cylinder, entering at one end and exhausting at the other. This design allows for more efficient steam utilization and reduced energy losses.

- Steam Rocket Engine: Steam rocket engines are used in experimental rocketry and space exploration. They operate by expelling high-pressure steam to generate thrust. While steam rocket engines have limited practical applications compared to other types, they have been used in research and development projects.

How Steam Engine Works

The steam engine works based on the principle of converting the energy of steam into mechanical power. Here is a simplified explanation of how a basic steam engine works:

- Boiler: The process begins with a boiler, where water is heated to generate steam. The boiler is typically fueled by burning coal, oil, or wood, or it may use nuclear energy or concentrated solar power for heat generation. The heat produced causes the water to boil, producing high-pressure steam.

- Cylinder and Piston: The steam is then directed into a cylinder, where a piston is housed. The cylinder has two ends, referred to as the head end and the crank end. The piston is a movable cylindrical component that fits snugly within the cylinder.

- Valve System: The movement of steam into and out of the cylinder is controlled by a valve system. In a reciprocating steam engine, the valve system consists of valves that open and close to allow steam to enter and exhaust from the cylinder at the appropriate times.

- Power Stroke: When steam enters the cylinder through the intake valve, it exerts pressure on the piston, causing it to move. This is known as the power stroke. As steam expands, it pushes the piston away from the cylinder head, converting the pressure energy of the steam into mechanical work.

- Exhaust Stroke: After the power stroke, the exhaust valve opens, allowing the used steam to exit the cylinder. The piston then moves back toward the cylinder head, driven either by the momentum of the flywheel or by a separate mechanism, such as a connecting rod and crankshaft.

- Condenser (in some cases): In certain types of steam engines, a condenser is used to condense the exhausted steam back into liquid water. This increases the efficiency of the engine by reducing energy losses. The condensed water is then returned to the boiler to be reheated and transformed into steam again.

- Flywheel: A flywheel is connected to the piston, which helps to smooth out the motion and store excess energy during the power stroke. The flywheel acts as a rotational inertia, maintaining a more uniform rotation of the engine.

- Power Output: The mechanical power generated by the reciprocating motion of the piston is typically used to drive machinery, such as locomotive wheels, factory equipment, or electrical generators, depending on the application of the steam engine.

How and where is steam engine made?

The production of steam engines involves various stages of manufacturing, assembly, and installation. Here is a general overview of how and where steam engines are made:

- Design and Engineering: Steam engines are designed and engineered by skilled professionals who specialize in mechanical engineering and related fields. The design process includes determining the specifications, dimensions, and performance characteristics of the steam engine.

- Foundry and Casting: Many components of a steam engine, such as the cylinder, piston, valve system, and various fittings, are typically made through casting. Foundries use specialized equipment to melt metal, usually iron or steel, and pour it into molds to create the desired shapes.

- Machining: Once the cast components are solidified, they go through machining processes. This involves using lathes, milling machines, drills, and other tools to shape and refine the components to precise specifications. Machining ensures that the parts fit together accurately and function smoothly.

- Assembly: The machined components are then assembled to construct the steam engine. Skilled technicians or engineers follow detailed assembly instructions to fit the various parts together, ensuring proper alignment and connection. This includes attaching the cylinder, piston, valves, connecting rods, and other essential components.

- Testing and Quality Control: Before the steam engine is ready for use, it undergoes rigorous testing and quality control procedures. This involves checking for proper functioning, verifying performance specifications, and identifying and rectifying any defects or issues.

- Installation and Integration: Depending on the application, steam engines are installed and integrated into the respective systems or machinery. For example, in steam locomotives, the engine is installed within the locomotive chassis and connected to the driving wheels. In power plants, steam engines may be integrated into turbine systems or used to drive electrical generators.

- Maintenance and Repair: Once in use, steam engines require regular maintenance and occasional repairs to ensure optimal performance and longevity. This includes routine inspections, lubrication, cleaning, and replacement of worn-out components.

As for where steam engines are made, historically, many steam engines were manufactured in dedicated factories that specialized in steam engine production. These factories were often located in industrial regions or areas with access to resources like coal and iron. Today, the production of steam engines has become less common as other forms of power generation and transportation have taken precedence. However, there are still specialized manufacturers and restoration companies that produce and refurbish steam engines for specific applications, such as heritage railways, steam-powered ships, and industrial machinery that requires steam power.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.

The article clearly explains the fundamental principles of steam engines, offering a concise and informative overview of their operation.

The steam engine, cracking invention that! Transformed everything, it did – railways, ships, factories. Made the world faster, more efficient. Of course, we’ve moved on to other things now, but we shouldn’t forget – it all started with steam.