What is a Positive Displacement pump?

WHAT IS A POSITIVE DISPLACEMENT PUMP?

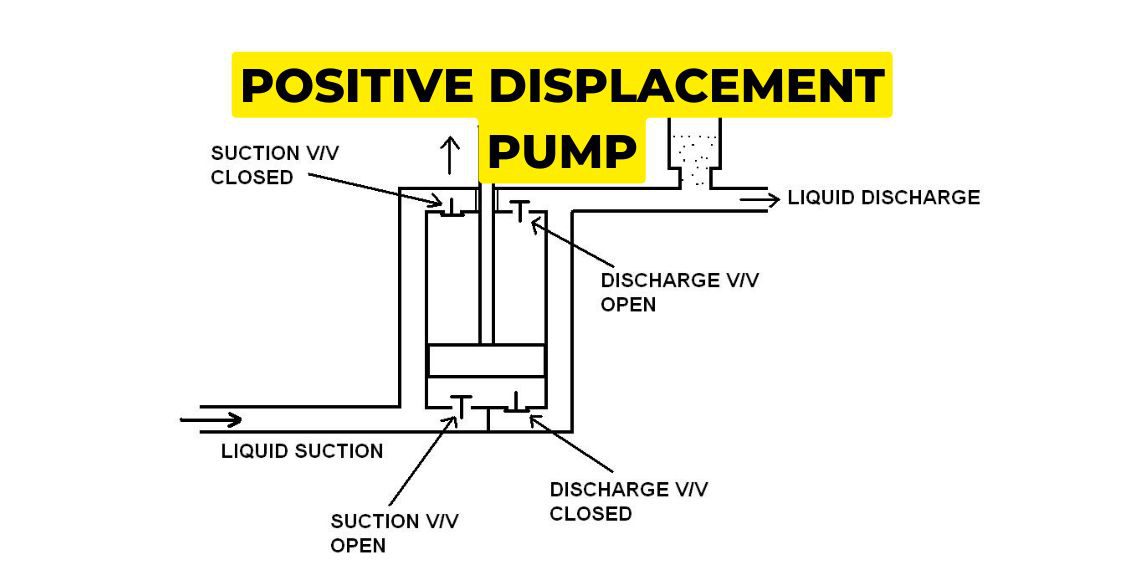

A positive displacement pump moves a fluid by repeatedly enclosing a fixed volume and moving it mechanically through the system. The pumping action is cyclic and can be driven by a piston, screw, gears, rollers, diaphragms, or vanes.

TYPES OF POSITIVE DISPLACEMENT PUMPS USED ON SHIPS:-

1. Reciprocating pump.

A. Diaphragm pump.

B. Piston pump:

i) single acting

ii) Double acting

2. Rotary pump

A. Screw pump

B. Gear pump

Diaphragm pump

“A diaphragm pump is a positive displacement pump that uses a combination of reciprocating action on a rubber, thermoplastic, or Teflon diaphragm, with suitable valves fitted on both the suction and delivery sides. This pump has a double-sided rubber or thermoplastic diaphragm of a specific size and shape that receives a reciprocating motion on the shaft, causing suction on one side and delivery on the other side. This continuous process results in a consistent water head delivery. The diaphragm pump is operated by compressed air.”

Piston pump (positive displacement pump)

A piston pump is a type of positive displacement pump where a piston moves back and forth inside a cylinder to displace and move fluids or gases. The pump works by creating pressure differentials in the cylinder through the reciprocating motion of the piston.

Single acting piston pump:

In a single-acting piston pump, the fluid is drawn into the cylinder through an inlet valve during the suction stroke and then discharged through a delivery valve during the discharge stroke. This type of pump is commonly used in various applications, such as in hydraulic systems, pressure washers, and water treatment plants.

Double acting piston pump:

In a double-acting reciprocating pump, the piston is fitted in the center of the cylinder. The figure shows two suction pipes fitted on one side and a delivery pipe on the other side, each with a valve system at the inlet and outlet ports. When the piston moves forward, the suction valve on the forward side is closed and the delivery valve is opened to deliver the fluid, while the suction valve on the other side of the cylinder is opened and the delivery valve is closed. Similarly, when the piston moves in reverse, the opposite occurs. Because of this, it is called a double-acting piston pump.

Rotary pump (positive displacement pump)

Rotary pumps are a type of positive displacement, where for every revolution a fixed amount of liquid is delivered through this process. These pumps are self-priming and provide near-constant delivered capacity no matter if the pressure will be very high.

Rotary pumps are two types

- Screw pump

- Gear pump

Screw pump:

A screw pump is a positive displacement pump that moves fluid through the rotary motion of one or more screws, which are rotated by a gear mechanism in the opposite direction. The fluid enters the pump through the inlet port, and as the screws rotate, the fluid is trapped and transported to the delivery port. This process continues, resulting in a continuous high-pressure fluid flow.”

Gear pump:

A gear pump is a type of positive displacement pump that uses two gears, with one gear fitted to the shaft and the other meshing with it. These two gears move in opposite directions, and when the pump starts, the inlet port opens, allowing water to flow into the casing where the gear teeth have minimal clearance. The water is then trapped between the teeth and transported to the outlet side. Due to the way the gears mesh, the water cannot flow back to the inlet side, resulting in the delivery of high-pressure fluid.”

WHAT WILL HAPPEN IF THE DISCHARGE VALVE SHUT AND THE POSITIVE DISPLACEMENT PUMP WILL START?

If the discharge valve is shut and the positive displacement pump is started, the pump will be unable to discharge any fluid or gas from its outlet because the discharge valve is closed, creating a condition called “deadheading” or “running against a closed valve”.

As the pump continues to operate against the closed valve, the pressure in the pump and the piping system will increase rapidly, as there is nowhere for the fluid or gas to go. This can cause damage to the pump and other components in the system and may result in the failure of the pump or the piping system.

In positive displacement pumps, the pressure generated by the pump increases rapidly as the pump operates against a closed valve. This can cause the pressure to exceed the design limits of the pump and the system, leading to mechanical failure or rupture of the piping.

To prevent damage in such situations, it is important to ensure that the discharge valve is open before starting the pump. If the discharge valve is accidentally closed while the pump is operating, the pump should be immediately shut off to prevent damage to the pump and the system.

Note:

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.