Testing of Material | Destructive Test | Non Destructive Tests | Difference between Destructive and Non Destructive Tests

A variety of destructive and non-destructive tests are carried out upon material to determine their suitability for use in engineering. The results are recorded and the results can be presented in tabular form.

The most common tests are explained below:

- Non-destructive Testing

- Destructive testing

Non-destructive testing:

Non-destructive testing (NDT) is a set of techniques and methods used to evaluate the properties and quality of materials, components, or structures without causing any permanent damage to them. NDT is essential in various industries, such as manufacturing, construction, aerospace, automotive, and marine to ensure the integrity and reliability of materials and products. The primary purpose of NDT is to identify defects, irregularities, or flaws in a non-invasive manner.

Some popular methods of NDT are :

Visual Examination:

Visual Testing (VT) is an optical method to check objects for defects. You can check with the naked eye as well as with tools like magnifying glasses or mirrors.

Liquid Penetration Testing:

The method leverages capillary action, i.e, the ability of a liquid to flow into narrow spaces without help, even in opposition to external forces such as gravity—to detect surface-breaking defects.

The excess is removed and a developer is applied after applying the penetrant and letting it dwell for a certain period. From surface-breaking defects, the developer draws the penetrant where it’s seeped, revealing their presence.

Electro-magnetic crack Detection:

It is the process of inducing electric currents or magnetic fields or both inside a test object and observing the electromagnetic response. If the test is set up properly, a defect inside the test object creates a measurable response.

Ultrasonic Testing:

High frequency sound waves are very directional, and they will travel through a medium (like a piece of steel or plastic) until they encounter a boundary with another medium (like air), at which point they reflect back to their source. By analyzing these reflections it is possible to measure the thickness of a test piece, or find evidence of cracks or other hidden internal flaws.

Radiography testing:

In Radiography Testing the test-part is placed between the radiation source and film. The material density and thickness differences of the test-part will reduce the penetrating radiation through interaction processes involving scattering and/or absorption. The differences in absorption are then recorded on film(s) or through electronic means.

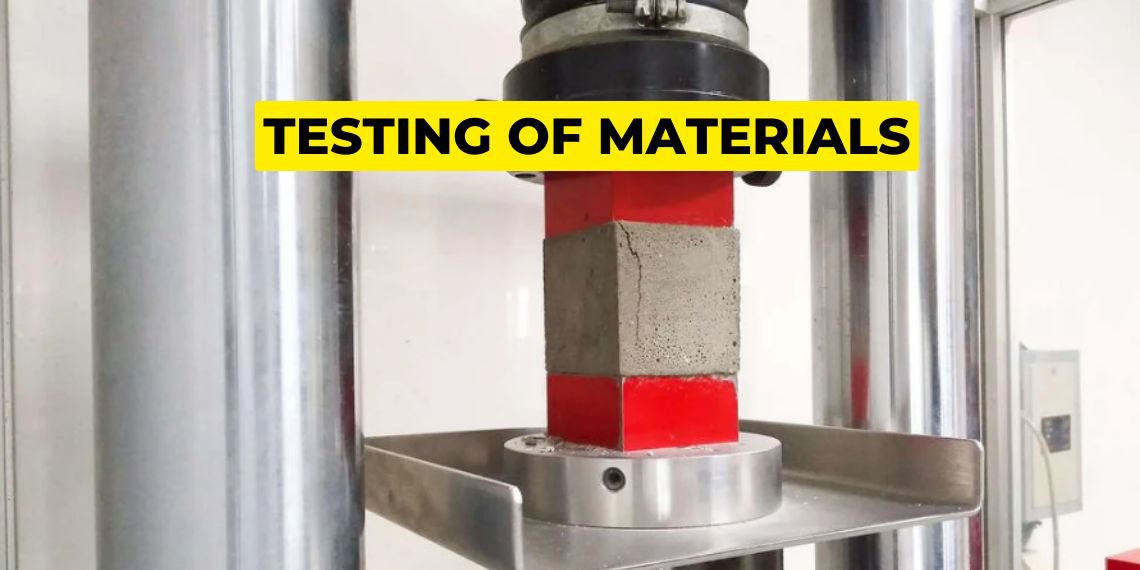

Destructive Testing:

Destructive testing (DT) is a set of testing methods used to assess the properties and performance of materials, components, or structures by subjecting them to controlled and often rigorous mechanical, thermal, or chemical processes that result in damage or failure.

Some popular methods of DT are :

Tensile Test:

This test is carried out to ascertain the strength and ductility of a material. The specimen is held in self-aligning grips and is subjected to a gradually increasing tensile load. An extensometer fitted across the specimen gives extension readings as the load is applied. With values of load plotted against the corresponding extension, a nominal stress-strain curve can be drawn.

Hardness Test

The hardness of a material determines its resistance to surface deformation due to impact or wear. These are the main tests used to determine the hardness of a material.

- Rockwell hardness test: Rockwell hardness test uses a small diamond cone or hard steel balls to carry out hardness tests.

2. Brinell Hardness Test: Brinell testing uses a larger diameter indenter, removing the variability caused by localised, structural differences and surface inconsistencies.

3. Vickers Hardness Test: The Vickers Hardness test uses a pyramid-shaped diamond indenter to carry out hardness testing. Like the other tests, the indenter is placed under a load and the permanent indentation is measured. However, this test often uses much lighter loads and can be used on softer materials.

4. Micro-hardness Test: Micro-hardness testing is used for very thin, layered samples of metals and extremely light loads, whereas macro hardness tests such as Brinell, Rockwell and Vickers perform hardness tests using loads typically from 1 kgf up to 3000 kgf.

Impact Test:

Impact tests are used in studying the toughness of material. A material’s toughness is a factor of its ability to absorb energy during plastic deformation.

Creep Test

It is defined as the slow plastic deformation of a material under constant stress. The creep test consists of applying a fixed load to a test piece which is maintained at a uniform temperature. This is a long term one and a number of specimens of the same material are subjected to this test simultaneously, all at different stresses but at the same temperature.

Fatigue Test

Fatigue may be defined as the failure of a material due to repeatedly applied stress. In this test a machine that can give a great number of stress reversals in a short duration of time is employed. The test is carried out on similar specimens of the same material at different stresses and the number of stress reversals to fracture is noted for each stress, normally 20 million reversals of stress reversal would not be exceeded if failure did not occur.

Bend Test

This test is carried out on boiler plate materials and consists of bending a straight plate specimen through 180° around a former. For the test to be satisfactory, no cracks should occur at the outer surface of the plate.

Difference between Destructive and Non Destructive tests

| Non Destructive Test | Destructive Test |

| Used for finding out defects of materials | Used for finding the properties of materials |

| Load is not applied on the material | Load is applied on the material |

| No load application, so no chance for material damage | Due to load application, material gets damaged |

| No requirements of special equipments | Special equipments are required |

| Non expensive | Expensive |

| Less Skill | Skill is required |

| Example: dye penetrant test, ultrasonic, radiography, etc | Example: tensile test, compression test, hardness test, etc |

Note:

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.